Advancing Low-Toxicity Vitrification Solutions for Mouse Embryo Cryopreservation: Strategies, Formulations, and Future Directions

This article provides a comprehensive resource for researchers and scientists on developing and optimizing low-toxicity vitrification solutions for mouse embryo cryopreservation.

Advancing Low-Toxicity Vitrification Solutions for Mouse Embryo Cryopreservation: Strategies, Formulations, and Future Directions

Abstract

This article provides a comprehensive resource for researchers and scientists on developing and optimizing low-toxicity vitrification solutions for mouse embryo cryopreservation. It covers foundational principles of cryoprotectant agent (CPA) toxicity and cellular injury mechanisms, explores innovative formulation strategies including binary CPA mixtures and commercial solutions like VEG, and details advanced methodologies such as ultra-fast vitrification to minimize osmotic stress. The content further addresses troubleshooting common challenges through high-throughput toxicity screening and quality control measures, and validates success through rigorous assessment of embryonic development, organelle integrity, and gene expression. By synthesizing current research and best practices, this guide aims to support improved cryopreservation outcomes in biomedical research and drug development.

Understanding Cryoprotectant Toxicity and Cellular Injury in Mouse Embryo Vitrification

Cryopreservation by vitrification represents a transformative approach in biomedical research, enabling long-term preservation of biological materials from single cells to complex tissues. This technique relies on the rapid cooling of high concentrations of cryoprotective agents (CPAs) to achieve a stable, ice-free glassy state that suspends all biochemical activity [1] [2]. However, researchers face a fundamental paradox: while higher CPA concentrations prevent lethal ice crystallization, they simultaneously introduce significant toxicity that can compromise cellular viability and function [3]. This challenge is particularly acute in mouse embryo cryopreservation, where maintaining developmental competence post-preservation is essential for reproductive research, genetic preservation, and drug development studies.

The toxicity of CPAs manifests through multiple mechanisms, including osmotic stress during addition/removal, direct chemical damage to cellular structures, and metabolic disruption [3] [4]. For mouse embryos, which are particularly sensitive to cryoprotectant exposure, finding the optimal balance between ice prevention and toxicity minimization is critical for successful vitrification outcomes. This application note examines current strategies to resolve this challenge through optimized CPA formulations, exposure protocols, and emerging technologies that collectively aim to enable high survival rates with preserved developmental potential.

Quantitative Analysis of CPA Toxicity Profiles

Table 1: Toxicity Rates of Scalable CPA Formulations in Kidney Tissue

| CPA Formulation | Total Concentration (M) | Toxicity Rate (k, minâ»Â¹) | Relative Toxicity | Reported Applications |

|---|---|---|---|---|

| VM3 | 8.46 | 0.007958 | 1.0x (reference) | Kidney slice vitrification |

| M22-PVP | 9.34 | 0.01755 | 2.2x | Rabbit kidney vitrification |

| M22 | 9.35 | 0.02339 | 2.9x | Rabbit kidney vitrification |

| VMP | 8.40 | Not reported | Intermediate | Rat kidney transplantation |

Table 2: Optimized CPA Mixtures for Mouse Oocyte Vitrification

| CPA Combination | Concentration in VS2 | Survival Rate (%) | Fertilization Rate (%) | Blastocyst Formation (%) |

|---|---|---|---|---|

| EG + Me₂SO | 20% + 20% | 69.2 ± 7.0 | 47.3 ± 2.7 | 38.8 ± 3.2 |

| GLY + PrOH | 20% + 20% | 42.1 ± 9.1 | 30.1 ± 4.7 | 26.1 ± 3.1 |

| EG alone | 40% | 20.7 ± 5.8 | 17.0 ± 3.2 | 8.0 ± 0.2 |

| Me₂SO alone | 40% | 8.9 ± 1.5 | 11.1 ± 0.5 | 5.6 ± 0.6 |

| Control (no CPA) | 0% | 92.1 ± 3.6 | 91.2 ± 5.5 | 74.2 ± 5.9 |

Recent systematic investigations reveal significant differences in toxicity profiles among common CPAs used in vitrification protocols. As shown in Table 1, formulations with similar osmotic concentrations can exhibit markedly different toxicity rates, with VM3 demonstrating approximately three-fold lower toxicity compared to M22 in kidney tissue models [3]. Similarly, Table 2 illustrates how strategic combination of CPAs can significantly improve outcomes compared to single-agent formulations, with EG + Meâ‚‚SO mixtures yielding substantially higher survival, fertilization, and blastocyst formation rates in mouse oocytes [5].

Mechanisms of Toxicity Reduction in CPA Mixtures

Mutual Dilution and Toxicity Neutralization

The improved performance of CPA mixtures stems from two primary mechanisms: mutual dilution and toxicity neutralization. Mutual dilution occurs when each CPA in a mixture effectively lowers the concentration of other CPAs, thereby reducing the overall toxic impact since CPA toxicity increases non-linearly with concentration [1]. Perhaps more importantly, toxicity neutralization describes the phenomenon where the addition of a second CPA partially counteracts specific toxic effects of the first CPA [1]. For instance, dimethyl sulfoxide (DMSO) has been shown to neutralize formamide toxicity, while similar neutralization effects occur between formamide and glycerol [1].

The molecular basis for these protective effects may involve stabilization of membrane structures, reduced perturbation of intracellular components, and moderation of osmotic stress. Research indicates that vascular endothelial cells—particularly vulnerable during cryopreservation and essential for post-transplant organ function—benefit significantly from these mixture effects [1]. For mouse embryos, which share similar sensitivity to osmotic and chemical stress, these principles can be strategically applied to design less toxic vitrification solutions.

Thermal Stress Considerations

Beyond direct chemical toxicity, the physical properties of CPA solutions significantly impact vitrification success. Higher glass transition temperatures (Tð‘”) have been correlated with reduced thermal stress cracking during temperature cycling [6]. Solutions with elevated Tð‘”, such as those containing sugars or sugar alcohols, exhibit lower thermal expansion coefficients, thereby minimizing the development of destructive thermal stresses during cooling and rewarming [6]. This physical stabilization complements the biochemical protection offered by optimized CPA mixtures.

Diagram 1: Mechanisms of Toxicity Reduction in CPA Mixtures. Strategic combination of CPAs provides synergistic protection through multiple complementary pathways.

High-Throughput Toxicity Screening Platform

Automated Methodology

Advanced screening platforms have revolutionized CPA development by enabling systematic evaluation of multiple formulations and exposure parameters. The Hamilton Microlab STARlet system represents one such automated liquid handling platform that permits precise control over CPA addition and removal sequences while randomizing treatments across 96-well plates to minimize positional bias [1]. This system facilitates high-throughput assessment of CPA toxicity using bovine pulmonary artery endothelial cells (BPAECs)—a relevant model for vascular-sensitive systems including the extensive vasculature of reproductive tissues.

The screening protocol involves several key steps. First, cells are cultured in standardized conditions in 96-well plates. Test CPAs are then applied using automated fluid handling with precise control over exposure duration and concentration gradients. After exposure, CPA removal is performed using multi-step dilution sequences to minimize osmotic shock. Finally, cell viability is quantified using metabolic indicators such as PrestoBlue, allowing calculation of toxicity rates and identification of promising formulations [1].

Application to Embryo Cryopreservation

While this platform utilizes endothelial cells, the fundamental principles of CPA toxicity are transferable to embryo cryopreservation. The high-throughput nature of this approach enables rapid screening of numerous CPA combinations and exposure parameters that would be impractical using embryo models directly. Promising candidates identified through initial screening can then be validated using mouse embryos in targeted follow-up studies, creating an efficient two-stage development pipeline for optimized vitrification solutions.

Protocol: Optimized Mouse Embryo Vitrification

Solution Preparation

Base Medium Preparation:

- Prepare HEPES-buffered medium supplemented with 20% fetal calf serum (FCS)

- Filter sterilize using 0.22µm membrane

- Store at 4°C for up to 1 week

Vitrification Solution (VS2):

- 20% ethylene glycol (v/v)

- 20% dimethyl sulfoxide (v/v)

- Base medium (as prepared above)

- Osmolarity: ~1500-1600 mOsm

- Prepare fresh before each experiment

Thawing Solutions:

- TS1: Base medium + 0.33 mol/L sucrose

- TS2: Base medium + 0.25 mol/L sucrose

- Equilibrate to room temperature before use

Vitrification Procedure

Equilibration Step: Transfer embryos to VS1 (containing 10% EG + 10% Meâ‚‚SO) for precisely 2 minutes at room temperature [5]

Vitrification Step: Move embryos to VS2 (20% EG + 20% Meâ‚‚SO) for 20 seconds at room temperature [5]

Loading and Cooling:

- Rapidly load embryos onto vitrification device (Open Pulled Straw or Nylon Loop)

- Immediately plunge into liquid nitrogen

- Ensure cooling rate exceeds 20,000°C/min [5]

Storage: Maintain embryos in liquid nitrogen or vapor phase below -150°C

Warming and CPA Removal

Rapid Warming:

- Remove vitrification device from liquid nitrogen

- Immediately immerse in TS1 pre-warmed to 37°C

- Hold for 3 minutes with gentle agitation [5]

Osmotic Adjustment:

- Transfer embryos to TS2 at room temperature

- Incubate for 3 minutes [5]

Recovery:

- Rinse embryos in base medium twice

- Transfer to culture medium for viability assessment

- Incubate under standard culture conditions (5% CO₂, 37°C)

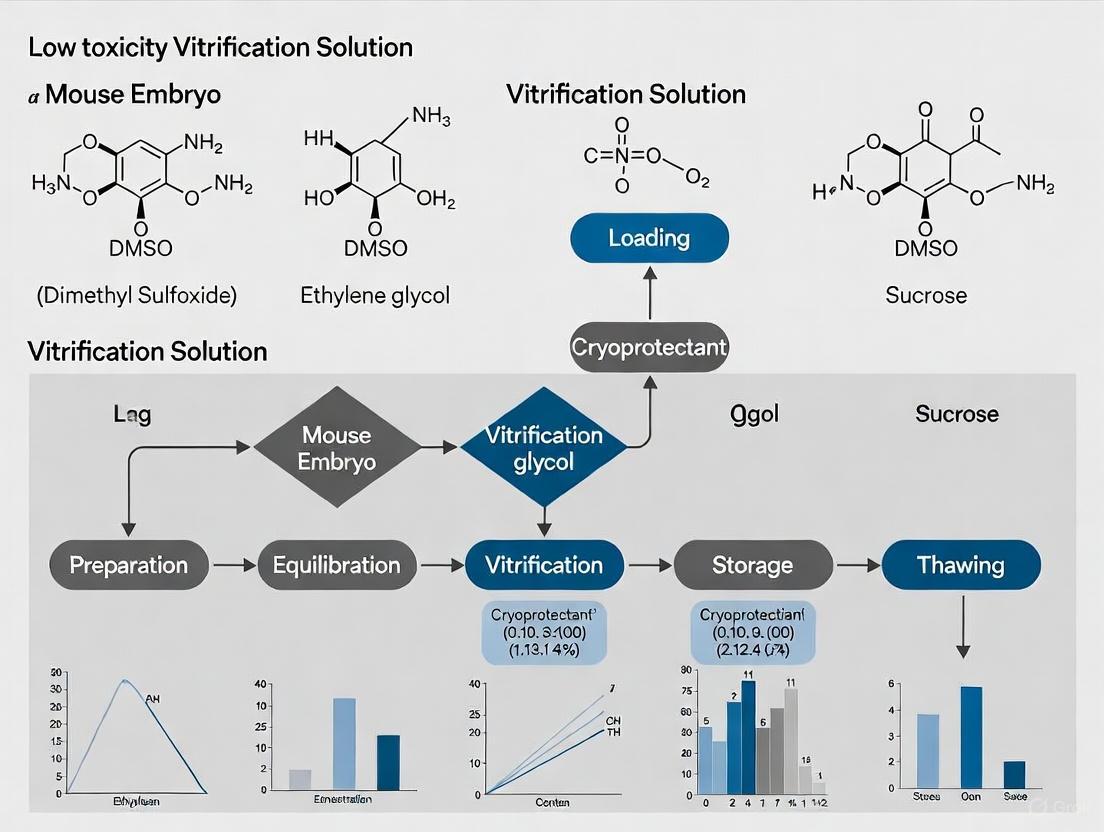

Diagram 2: Mouse Embryo Vitrification Workflow. The optimized protocol emphasizes precise timing and temperature control at each transition point to minimize cumulative toxicity.

Advanced Rewarming Strategies

Nanowarming Technology

Conventional convective warming methods often produce insufficient warming rates and temperature non-uniformity that promotes ice crystallization and thermal stress damage [7] [2]. Nanowarming represents a breakthrough approach that addresses these limitations by generating heat volumetrically throughout the vitrified specimen [2]. This technique involves perfusing iron oxide nanoparticles (IONPs) throughout the vascular system prior to vitrification, then applying alternating magnetic fields to generate uniform heat distribution during rewarming [2].

While initially developed for larger organs, the principles of nanowarming could be adapted to embryo systems through modified nanoparticle delivery systems. The demonstrated success of nanowarming in recovering viable kidneys after 100 days of cryopreservation highlights its potential for revolutionizing cryopreservation outcomes across biological scales [2].

Optimization Parameters

Successful nanowarming requires careful optimization of several parameters:

- IONP concentration (typically 10 mg Fe/mL in final CPA solution)

- Perfusion pressure and flow rates to ensure uniform distribution

- Magnetic field strength and frequency (e.g., 63 kA/m at 180 kHz)

- Warming rates exceeding 70°C/min to prevent ice crystallization [2]

The Scientist's Toolkit: Essential Research Reagents

Table 3: Essential Reagents for Low-Toxicity Vitrification Research

| Reagent Category | Specific Examples | Function | Application Notes |

|---|---|---|---|

| Penetrating CPAs | Ethylene Glycol (EG), Dimethyl Sulfoxide (Meâ‚‚SO), Propylene Glycol | Intracellular ice inhibition, glass formation | EG + Meâ‚‚SO mixtures show superior toxicity profiles [5] |

| Non-penetrating CPAs | Sucrose, Trehalose, Ficoll, PVP | Osmotic buffering, extracellular stabilization | Critical for controlling edema during CPA removal |

| Biocompatible Additives | Fetal Calf Serum (20%) | Membrane stabilization, reduced toxicity | Optimal at 20% concentration in vitrification solutions [5] |

| Nanowarming Components | Silica/PEG-coated IONPs | Volumetric heating during rewarming | Enable uniform warming >70°C/min [2] |

| Viability Assays | PrestoBlue, Calcein-AM, Propidium Iodide | Quantification of post-warming survival | High-throughput compatibility essential for screening [1] |

| Naphazoline | Naphazoline HCl | High-purity Naphazoline hydrochloride for research. A potent alpha-adrenergic receptor agonist for pharmacological studies. For Research Use Only. | Bench Chemicals |

| Naproxen Etemesil | Naproxen Etemesil, CAS:385800-16-8, MF:C17H20O5S, MW:336.4 g/mol | Chemical Reagent | Bench Chemicals |

Balancing ice prevention with CPA toxicity remains a critical challenge in mouse embryo cryopreservation, but strategic approaches are emerging to address this fundamental paradox. The integration of optimized CPA mixtures, precise exposure protocols, advanced rewarming technologies, and high-throughput screening platforms creates a comprehensive framework for developing effective, low-toxicity vitrification solutions. As these technologies mature, they promise to enhance the efficiency and reliability of mouse embryo cryopreservation, supporting advancements in reproductive research, genetic preservation, and pharmaceutical development.

The successful application of these principles in complex systems—from kidney vitrification to oocyte cryopreservation—demonstrates their potential for transforming embryo cryopreservation outcomes. Future research should focus on adapting these approaches specifically for mouse embryo models, with particular attention to developmental stage-specific responses and long-term functional assessment of cryopreserved embryos.

Cryopreservation is a critical technique for the long-term storage of biological materials, including mouse embryos, essential for biomedical research and drug development. The success of these protocols, particularly those employing low-toxicity vitrification solutions, hinges on understanding and mitigating the principal mechanisms of cellular injury. These mechanisms—chilling damage, osmotic shock, and intracellular ice formation—represent significant barriers to post-thaw viability [8] [9]. This Application Note details the underlying theories and provides standardized protocols to quantify these injuries, providing a framework for researchers developing and optimizing novel, low-toxicity cryopreservation formulations for mouse embryos.

Mechanisms of Cryoinjury

The journey of a cell to cryogenic temperatures and back to a physiological state exposes it to a series of physical and chemical stresses. The following sections delineate the primary injury mechanisms.

Chilling Damage

Chilling injury occurs at temperatures above the freezing point of the solution but low enough to disrupt cellular metabolism and structure. This damage is independent of ice formation and is particularly relevant for temperature-sensitive cell types.

- Molecular Mechanisms: The fundamental cause is the thermotropic phase transition of membrane lipids from a liquid-crystalline to a gel state. This phase change compromises membrane integrity, leading to increased permeability and the leakage of intracellular components [8]. Furthermore, low temperatures can induce cold denaturation of proteins, disrupt the cytoskeleton, and inactivate critical enzymes, thereby halting development.

- Biological Consequences: In mouse embryos, chilling injury can manifest as irreversible damage to the meiotic spindle in oocytes, leading to aneuploidy, and as a general reduction in developmental competence post-thaw.

Osmotic Shock

Osmotic shock is a consequence of the dramatic cell volume changes during the addition and removal of cryoprotective agents (CPAs) and during the freezing process itself [10].

- Theoretical Basis: During CPA addition or freezing (where extracellular ice formation concentrates solutes), water exits the cell rapidly, causing excessive cell shrinkage. Conversely, during CPA dilution or thawing, water influx can cause the cell to swell beyond its critical volume. The two-factor hypothesis of freezing injury posits that these osmotic volume excursions, alongside intracellular ice formation, are key determinants of cell survival [9].

- Cellular Impact: Excessive shrinkage can lead to the collapse of intracellular structures and damage to the plasma membrane. The subsequent swelling can cause membrane rupture (lysis). The "osmotic rupture hypothesis" further suggests that the osmotic pressure gradient during freezing can itself stress the membrane to the point of failure, creating pores that permit intracellular ice formation [11].

Intracellular Ice Formation (IIF)

IIF is widely considered the most lethal event during rapid cooling, as it directly disrupts and pierces subcellular structures [9].

- Mechanisms of IIF: IIF does not occur spontaneously but is catalyzed by the extracellular environment. Two primary mechanisms are:

- Surface-Catalyzed Nucleation: Extracellular ice grows through membrane pores or invaginations, seeding the supercooled cytoplasm.

- Plasma Membrane Rupture: Osmotically driven water efflux generates sufficient pressure to rupture the plasma membrane, allowing extracellular ice to propagate into the cell [11].

- Propagation and the Role of Cell Junctions: In tissues and cell aggregates, IIF can propagate from one cell to its neighbors. Recent research using high-speed videomicroscopy has revealed that this propagation is facilitated not only by gap junctions but also by the penetration of ice into the paracellular space between cells, highlighting a complex dependence on intercellular junction protein expression [9].

The following diagram illustrates the logical progression and key events leading to these three primary injury mechanisms during a cryopreservation cycle.

Logical relationships of primary cryoinjury mechanisms.

Quantitative Data on Cryoinjury

Understanding the quantitative impact of key variables is crucial for protocol optimization. The following tables summarize critical data on cryoprotectant toxicity and the dynamics of ice formation.

Table 1: Comparative Toxicity of Common Penetrating Cryoprotectants in Model Systems

| Cryoprotectant | Test System | Key Toxicity Findings | Experimental Conditions | Reference |

|---|---|---|---|---|

| Dimethyl Sulfoxide (DMSO) | Dermal Fibroblasts | Viability decreased with increasing concentration, temperature, and exposure time. | 5-30% (v/v), 4-37°C, 10-30 min | [8] |

| Ethylene Glycol (EG) | Mouse Zygotes | 30% and 40% EG yielded 98% and 84% development to blastocysts, respectively. | 20°C for 20 min exposure | [12] |

| Glycerol (GLY) | Stallion Sperm | Concentrations >1.5% polymerized actin cytoskeleton. | N/A | [8] |

| L-Proline | Mouse Oocytes | 2M L-proline significantly improved survival vs. proline-free control (94.7% vs 88.4%). | Vitrification/Warming | [13] |

| Propylene Glycol (PG) | Mouse Zygotes | >2.5 M impaired developmental potential by decreasing intracellular pH. | N/A | [8] |

Table 2: Ice Formation Dynamics in Bovine Oocytes Under Different Conditions

| Cooling Rate | Warming Rate | CPA Concentration | Ice Formation after Cooling | Ice Formation during Warming | Reference |

|---|---|---|---|---|---|

| ~30,000 °C/min | Conventional | Standard Vitrification Solution | None detected | Large ice fractions (most free water crystallizes) | [14] |

| ~600,000 °C/min | Conventional | Standard Vitrification Solution | Essentially none | Essentially none | [14] |

| ~30,000 °C/min | High Convective (20x conventional) | Reduced CPA concentration | To be determined | To be determined (enables lower CPA use) | [14] |

Experimental Protocols

This section provides detailed methodologies for assessing cellular injury, utilizing mouse embryos or other relevant biological models.

Protocol: Assessing Osmotic Shock and Membrane Integrity During CPA Equilibration

This protocol measures cell volume changes and membrane damage during the loading and unloading of CPAs.

1. Materials:

- Log-phase mouse morulae or zygotes.

- Equilibration Medium: PB1 medium with 3.0 M Ethylene Glycol.

- Vitrification Medium: PB1 medium with 40% Ethylene Glycol and 30% Ficoll (EFS solution) [12].

- Dilution Medium: PB1 medium with 0.5 M sucrose.

- Microscope with camera and image analysis software.

- Hemocytometer or automated cell counter.

- Trypan Blue stain.

2. Method: 1. Baseline Measurement: Place a cohort of embryos (n≥20) in a culture drop and record their initial diameters using image analysis. 2. CPA Loading: * Transfer embryos to Equilibration Medium at 20°C for 5-7 minutes. * Capture images every 30 seconds to track volume changes. * Calculate cell volume assuming spherical geometry. 3. Vitrification Solution Exposure: Transfer embryos to Vitrification Medium for 2-5 minutes at 20°C. Note: For toxicity assessment, this step can be performed without actual cooling. 4. CPA Unloading (Simulated Thaw): * Transfer embryos directly to Dilution Medium. * Capture images to monitor swelling over 10 minutes. 5. Viability Assessment: Incubate embryos with Trypan Blue stain (0.4%) for 3-5 minutes. Cells with compromised membranes will take up the blue dye. 6. Culture: Wash embryos and place in culture medium to assess developmental competence to the blastocyst stage over 5 days.

3. Data Analysis:

- Plot normalized cell volume versus time to visualize shrinkage and swelling kinetics.

- Calculate the percentage of Trypan Blue positive cells for each treatment group.

- Compare blastocyst formation rates between experimental and untreated control groups.

Protocol: Quantifying Intracellular Ice Formation Using High-Speed Videomicroscopy

This protocol utilizes a controlled freezing stage and high-speed imaging to directly observe the nucleation and propagation of IIF.

1. Materials:

- Mouse insulinoma MIN6 cells (wild-type and junction-protein knockdown strains).

- Cryostage with temperature controller (e.g., Linkam or similar).

- High-speed video camera (≥1000 fps).

- Inverted microscope with 40x or 60x objective.

- CPA solution (e.g., 1.5-2.0 M DMSO in culture medium).

2. Method: 1. Sample Preparation: Culture cells to form confluent monolayers or two-cell pairs on cryostage-compatible dishes. For knockdown studies, use cells with targeted knockdown of gap, adherens, and tight junction proteins [9]. 2. CPA Equilibration: Incubate cells in CPA solution for 10-15 minutes at room temperature. 3. Mounting and Cooling: * Place the sample on the cryostage. * Initiate a rapid cooling ramp (e.g., 130°C/min) from a supra-zero temperature (e.g., 0°C) down to -50°C or lower. * Simultaneously, begin high-speed video recording. 4. Observation: Visually track the sample for the characteristic darkening or "flashing" that indicates IIF. Note the temperature of first ice formation and the pattern of cell-to-cell propagation.

3. Data Analysis:

- Review high-speed videos to determine the nucleation temperature for the first and subsequent cells.

- Calculate the probability of IIF propagation between cell pairs.

- Compare propagation rates and nucleation temperatures between wild-type and junction-protein-deficient cells to elucidate the role of intercellular connections [9].

The workflow for this detailed analysis is outlined below.

High-speed videomicroscopy workflow for IIF quantification.

The Scientist's Toolkit: Research Reagent Solutions

Selecting the appropriate reagents is fundamental to successfully investigating cryoinjury and developing improved vitrification solutions.

Table 3: Essential Reagents for Investigating Cryoinjury Mechanisms

| Reagent / Solution | Function / Utility | Application Example |

|---|---|---|

| Ethylene Glycol (EG) | A penetrating CPA with relatively low toxicity. Often a key component of low-toxicity vitrification solutions. | Used at 40% with Ficoll and sucrose (EFS solution) for mouse morulae vitrification with high survival and live birth rates [12]. |

| L-Proline | A natural, nontoxic amino acid acting as an osmoprotectant and antioxidant. Reduces osmotic and oxidative stress. | Supplementation at 2M in vitrification solution significantly improved survival and mitochondrial function in mouse oocytes [13]. |

| Synth-a-Freeze Medium | A chemically defined, protein-free, ready-to-use cryopreservation medium. Eliminates variability from serum. | Standardized cryopreservation of stem and primary cells, ensuring consistency in toxicity studies [15]. |

| Polyvinyl Alcohol (PVA) | A synthetic polymer that inhibits ice nucleation, growth, and recrystallization. A non-penetrating cryoprotectant. | Used at 1 mg/mL to reduce ice crystal growth and improve survival of bacteria during cryopreservation; applicable to cellular systems [16]. |

| Ficoll | A high-molecular-weight polymer used as a non-penetrating CPA to increase solution viscosity and aid vitrification. | A component of EFS vitrification solution, helping to achieve a glassy state without ice crystallization [12]. |

| Trehalose | A non-penetrating disaccharide that stabilizes membranes and proteins during dehydration and freezing. | Used in combination with PVA (50 mg/mL) as a low-toxicity alternative for microorganism cryopreservation [16]. |

| 2-[[(E)-octadec-9-enoyl]amino]ethyl dihydrogen phosphate | 2-[[(E)-octadec-9-enoyl]amino]ethyl dihydrogen phosphate, CAS:24435-25-4, MF:C20H40NO5P, MW:405.5 g/mol | Chemical Reagent |

| Phthalylsulfacetamide | Phthalylsulfacetamide, CAS:131-69-1, MF:C16H14N2O6S, MW:362.4 g/mol | Chemical Reagent |

Within the field of mouse embryo cryopreservation research, the development of low-toxicity vitrification solutions is paramount for ensuring high post-warm viability and maintaining developmental competence. Permeating cryoprotectants (CPAs), which enter the cell to prevent lethal intracellular ice formation, are indispensable components of these solutions. However, their inherent cytotoxicity poses a significant challenge. This Application Note provides a detailed comparative analysis of the toxicity profiles of three predominant permeating CPAs—Dimethyl Sulfoxide (DMSO), Ethylene Glycol (EG), and Glycerol—framed within the context of optimizing vitrification protocols for mouse embryos. We summarize key quantitative toxicity data, present detailed experimental methodologies for its assessment, and provide essential resources to support research into next-generation, low-toxicity cryopreservation formulations.

Toxicity Profiles and Data Comparison

The toxicity of a CPA is not an absolute value but is influenced by concentration, exposure time, temperature, and the biological system itself. The data below provide a comparative overview of these agents under conditions relevant to embryo vitrification.

Table 1: Comparative Toxicity Profiles of Common Permeating Cryoprotectants

| Cryoprotectant | Typical Vitrification Concentration | Key Toxicity Mechanisms | Reported IC50 / Toxic Threshold (Mammalian Cells) | Temperature Dependence |

|---|---|---|---|---|

| DMSO | ~1.5 - 3.0 M (10-20% v/v) [17] [18] | - Induces DNA demethylation; alters epigenetic landscape [19]- Disrupts membrane integrity & mitochondrial function [17]- Increases reactive oxygen species (ROS) production [17] | - Significant toxicity to human chondrocytes at 6 M and 8.1 M (37°C) [17]- Toxicity rate constant (k): 2.62 (at 6 mol/kg) [20] | High toxicity at elevated temperatures; rapid cooling after addition is critical [17] |

| Ethylene Glycol (EG) | ~3.0 - 6.0 M [1] | - Generally lower chemical toxicity than DMSO [17] [20]- Primary risk is osmotic shock during addition/removal | - Toxicity rate constant (k): 0.59 (at 6 mol/kg) [20] | Toxicity increases with temperature, but less pronounced than DMSO [17] |

| Glycerol | ~3.0 - 6.0 M [1] [17] | - Lower chemical toxicity than DMSO [17]- Can cause osmotic stress and damage due to slower permeability in some cell types [17] | - Toxicity rate constant (k): 0.34 (at 6 mol/kg) [20] | Cytotoxicity increases with higher temperatures; strict temperature control is essential [17] |

Table 2: Toxicity Rate Constants (k) for Single and Binary CPA Solutions at 6 mol/kg and Room Temperature [20]

| CPA Solution | Toxicity Rate Constant (k) |

|---|---|

| DMSO | 2.62 |

| Ethylene Glycol (EG) | 0.59 |

| Glycerol | 0.34 |

| Formamide | 0.61 |

| Propylene Glycol (PG) | 0.48 |

| Binary Mixture (DMSO + EG) | 1.06 |

| Binary Mixture (DMSO + Glycerol) | 0.95 |

Experimental Protocols for Toxicity Assessment

To evaluate CPA toxicity in the context of mouse embryo vitrification, the following high-throughput and embryo-specific protocols are recommended.

High-Throughput Toxicity Screening in Cell Models

This automated protocol enables rapid screening of multiple CPA formulations and is ideal for initial toxicity neutralization studies [1] [20].

1. Cell Preparation:

- Culture bovine pulmonary artery endothelial cells (BPAECs) or another relevant cell line in 96-well plates until ~80% confluent.

- Include control wells for background (cell-free media) and 100% viability (cells with no CPA exposure).

2. Automated CPA Addition:

- Use an automated liquid handling system (e.g., Hamilton Microlab STARlet) for precise, serial dilution and addition of CPA solutions to the wells.

- Employ a multi-step addition protocol to minimize osmotic shock. Randomize the placement of CPA treatments across the plate to avoid positional bias.

- Expose cells to the target CPA concentration (e.g., up to 6 mol/kg) for a defined duration (e.g., 5-30 minutes) at room temperature.

3. CPA Removal and Viability Assay:

- Remove CPA solutions using a step-wise dilution process with isotonic buffer.

- Add a cell viability indicator, such as PrestoBlue, to the wells.

- Incubate according to the manufacturer's instructions and measure fluorescence using a plate reader.

- Calculate normalized viability relative to the 100% viability control wells.

Toxicity and Functional Assessment in Mouse Embryos

This protocol directly assesses the impact of CPAs on embryo development and health, providing functional data for vitrification solution optimization [19].

1. Embryo Collection & Culture:

- Collect 8-cell stage mouse embryos following standard superovulation and mating protocols.

- Maintain embryos in pre-equilibrated culture medium under oil at 37°C and 5% CO₂.

2. CPA Exposure and Vitrification Simulation:

- Transfer embryos through a series of equilibration and vitrification solutions containing the CPA(s) of interest (e.g., 7.5% DMSO + 7.5% EG vs. 7.5% PG + 7.5% EG).

- Control the exposure time meticulously (e.g., 5 min in equilibration solution, 30 sec in vitrification solution) at room temperature to simulate vitrification conditions without plunging into liquid nitrogen.

- For toxicity neutralization tests, include groups with additives like N-acetyl-l-cysteine (NAC, 5 mM) in the DMSO-based vitrification medium [19].

3. Post-Exposure Analysis:

- Developmental Competence: Culture the embryos for 5 days to the blastocyst stage and record the rates of development.

- Epigenetic Analysis: Fix a subset of embryos at the 8-cell or blastocyst stage. Perform immunostaining for 5-methylcytosine (5mC) and 5-hydroxymethylcytosine (5hmC) to quantify DNA methylation changes [19].

- Gene Expression: Extract RNA from blastocysts for RNA-sequencing analysis to examine changes in key signaling pathways (e.g., MAPK, Wnt) and expression of DNA methyltransferases (DNMTs) and demethylases (TETs) [19].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for CPA Toxicity and Vitrification Research

| Reagent / Solution | Function / Application | Example Use in Protocol |

|---|---|---|

| DMSO (High Purity) | Penetrating CPA; standard for many vitrification protocols but with known toxicity risks. | Positive control for toxicity studies; component of standard vitrification solutions [17] [18]. |

| Ethylene Glycol (EG) | Penetrating CPA; often used in mixtures for lower toxicity and rapid permeability. | Combined with DMSO or PG in vitrification solutions to reduce total toxicity load [19] [1]. |

| Propylene Glycol (PG) | Penetrating CPA; investigated as a lower-toxicity alternative to DMSO. | Used in vitrification solutions to mitigate DMSO-induced DNA demethylation [19]. |

| N-Acetyl-L-Cysteine (NAC) | Antioxidant; acts as a toxicity neutralization agent. | Added at 5 mM to DMSO-based vitrification media to ameliorate oxidative stress and DNA demethylation [19]. |

| Trehalose | Non-penetrating CPA; provides extracellular stabilization and reduces osmotic stress. | Component of vitrification and slow-freeze solutions (e.g., 0.1 M - 0.4 M) to improve post-warm survival [21]. |

| PrestoBlue / MTT Cell Viability Reagent | Metabolic activity indicator for quantitative toxicity assessment. | Used in high-throughput screening to measure cell viability after CPA exposure [1]. |

| Anti-5mC / Anti-5hmC Antibodies | Immunostaining reagents for epigenetic analysis. | Used to quantify global DNA methylation and hydroxymethylation levels in embryos post-CPA exposure [19]. |

| Bemfivastatin | Bemfivastatin, CAS:805241-79-6, MF:C34H37FN2O6, MW:588.7 g/mol | Chemical Reagent |

| Necrostatin-7 | Necrostatin-7, CAS:351062-08-3, MF:C16H10FN5OS2, MW:371.4 g/mol | Chemical Reagent |

Visualizing Toxicity Pathways and Experimental Workflows

Molecular Pathways of DMSO-Induced Toxicity in Embryos

The following diagram illustrates the key molecular mechanisms of DMSO-induced toxicity as identified in recent research, particularly the pathway leading to DNA demethylation.

High-Throughput Workflow for CPA Toxicity Screening

This workflow outlines the automated process for screening cryoprotectant toxicity, from plate preparation to data analysis.

In the field of assisted reproductive technology, vitrification has become the gold standard for cryopreserving mouse oocytes and embryos. A key challenge in protocol optimization lies in balancing the exposure time to cryoprotective agents with the osmotic stress placed on the cell. The permeability characteristics of the oocyte and embryo membranes are a central factor in this balancing act, directly influencing the optimal CPA exposure time and the potential for osmotic damage. This application note explores the relationship between membrane permeability, CPA exposure time, and cellular damage, providing researchers with detailed protocols and data to inform the development of low-toxicity vitrification solutions for mouse embryo cryopreservation.

Theoretical Framework: Permeability, Osmosis, and Toxicity

The permeability of cellular membranes to water and CPAs governs the kinetics of dehydration and CPA permeation during the vitrification process. Understanding these principles is essential for designing effective protocols.

Permeating vs. Non-Permeating Agents: Vitrification solutions typically contain a combination of permeating CPAs and non-permeating agents. Permeating CPAs include ethylene glycol and dimethyl sulfoxide, which cross the cell membrane and help prevent intracellular ice formation. Non-permeating agents include sucrose and trehalose, which create an osmotic gradient that drives cellular dehydration prior to vitrification [22]. This dehydration is critical for reducing intracellular ice formation.

Osmotic Stress and Volumetric Changes: During CPA addition and removal, cells undergo significant volumetric changes. The addition of CPAs causes initial cell shrinkage as water exits, followed by a return to original volume as CPA and water enter. This process reverses during CPA removal. Excessive osmotic stress can cause irreversible damage to the cytoskeleton and cellular organelles [23].

Toxicity and Exposure Time: Permeating CPAs become toxic with prolonged exposure. The relationship between exposure time and toxicity is concentration-dependent, with higher CPA concentrations requiring shorter exposure times. Ultra-rapid vitrification protocols aim to minimize this toxic stress by reducing CPA exposure time through increased cooling rates [24] [25].

Figure 1: Concentration-dependent toxicity pathway. Membrane permeability influences both osmotic stress and CPA toxicity, which converge to cause cellular damage. Optimal exposure time modulates this pathway to minimize detrimental effects.

Quantitative Data on Embryonic Development Post-Vitrification

The developmental stage of embryos significantly impacts their survival and developmental competence after vitrification. Later-stage embryos generally show higher resilience.

Table 1: Developmental Competence of Mouse Embryos After Vitrification at Different Stages

| Developmental Stage | Morphologically Normal after Warming (%) | Developed to Blastocyst (%) | References |

|---|---|---|---|

| Zygote | 72 | 16 | [23] |

| 2-Cell | 86 | 25 | [23] |

| 4-Cell | 90 | 71 | [23] |

| 8-Cell | 93 | 80 | [23] |

| Morula | 97 | 92 | [23] |

| Blastocyst | 90-93* | N/A | [22] |

Note: *Survival rate of artificially shrunken blastocysts vitrified in sucrose- and Ficoll-free solution.

Table 2: Impact of Vitrification Method on Mouse Oocyte Organelle Integrity

| Parameter | Fresh Oocytes (Control) | Conventional Vitrification (C-VIT) | Ultra-Fast Vitrification (UF-VIT) | References |

|---|---|---|---|---|

| Survival Rate | 100% | 95.2%* | 98.5% | [25] |

| Normal ER Distribution (Equatorial) | 92% | 66%* | 84% | [25] |

| Normal Mitochondrial Distribution | 86% | 14%* | 46%* | [25] |

| Mitochondrial Membrane Potential (ΔΨm) | 0.80 | 0.61* | 0.79 | [25] |

| Blastocyst Formation Rate | Baseline | Significantly reduced vs. control* | No significant difference vs. control | [25] |

Note: *Statistically significant difference (p < 0.05) compared to control group.

Detailed Experimental Protocols

Protocol 1: Ultra-Fast Vitrification (UF-VIT) of Mouse Oocytes

This protocol minimizes CPA exposure time to reduce toxicity and osmotic stress, based on the method described by Jin and Mazur [25].

Materials:

- Equilibration Solution: 7.5% ethylene glycol + 7.5% DMSO in base medium

- Vitrification Solution: 15% ethylene glycol + 15% DMSO + 0.5M sucrose in base medium

- Warming Solution 1: 1.0M sucrose in base medium at 37°C

- Warming Solution 2: 0.5M sucrose in base medium at room temperature

- Base medium: PBS supplemented with 20% serum substitute supplement

- Quartz capillaries or Cryotop/Cryoloop devices

- Liquid nitrogen

Procedure:

- Equilibration: Transfer oocytes into equilibration solution for 30-60 seconds at room temperature. Observe for initial shrinkage and partial return to original volume.

- Vitrification Solution Exposure: Immediately transfer oocytes to vitrification solution. Limit exposure time to 20-30 seconds.

- Loading and Cooling: Within 30 seconds of exposure to vitrification solution, load oocytes onto quartz capillaries or Cryotop devices and plunge directly into liquid nitrogen.

- Warning: Warm samples rapidly by immersing in Warming Solution 1 at 37°C for 3 minutes.

- Sucrose Dilution: Transfer oocytes to Warming Solution 2 for 5 minutes at room temperature.

- Final Rinse: Wash oocytes twice in base medium for 5 minutes each.

- Assessment: Evaluate survival rates and culture for further development.

Protocol 2: Vitrification of Mouse Embryos at Different Developmental Stages

This protocol adapts CPA exposure times based on embryonic stage, using Open Pulled Straws as containers [23].

Materials:

- Vitrification Solution 1: 7.5% EG + 7.5% DMSO in base medium

- Vitrification Solution 2: 15% EG + 15% DMSO + 0.5M sucrose in base medium

- Thawing Solution 1: 0.5M sucrose in base medium at 37°C

- Thawing Solution 2: 0.25M sucrose in base medium at room temperature

- Base medium: PBS supplemented with 20% serum substitute supplement

- Open Pulled Straws

- Liquid nitrogen

Procedure:

- Preparation: Prepare OPS by heating and pulling 0.25mL straws to achieve a thin wall.

- Equilibration: Expose embryos to Vitrification Solution 1 for 4 minutes at room temperature.

- Vitrification Solution Transfer: Move embryos to Vitrification Solution 2 for 40 seconds.

- Loading and Cooling: Load 1-3 embryos into OPS and plunge into liquid nitrogen within 40 seconds.

- Warning: Thaw straws by immersing narrow end directly into Thawing Solution 1 at 37°C.

- Sucrose Removal: Transfer embryos to Thawing Solution 2 for 3 minutes.

- Final Rinse: Wash embryos in base medium for 3 minutes.

- Culture: Culture embryos in appropriate medium for developmental assessment.

Protocol 3: Mitochondrial and ER Integrity Assessment Post-Vitrification

This protocol assesses subcellular organelle damage after vitrification.

Materials:

- Mito-Tracker Red CMXRos (for mitochondrial membrane potential)

- ER-Tracker Blue-White DPX dye

- Hoechst 33342 (for nuclear staining)

- Microtubule staining kit for spindle visualization

- Confocal microscopy equipment

Procedure:

- Staining: Co-incubate warmed oocytes/embryos with Mito-Tracker Red and ER-Tracker dyes for 30 minutes.

- Fixation: Fix samples in paraformaldehyde for 15 minutes.

- Microtubule Staining: Perform immunostaining for microtubules to visualize meiotic spindles.

- Nuclear Staining: Counterstain with Hoechst 33342.

- Imaging: Capture images using confocal microscopy with appropriate filters.

- Analysis: Assess mitochondrial distribution, ER patterns, and spindle morphology compared to fresh controls.

Figure 2: Ultra-fast vitrification workflow. Critical timing steps minimize CPA exposure while ensuring sufficient dehydration. Exposure times must be optimized based on membrane permeability characteristics.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Low-Toxicity Vitrification Research

| Reagent/Category | Specific Examples | Function & Application Notes |

|---|---|---|

| Permeating CPAs | Ethylene glycol, Dimethyl sulfoxide, Glycerol | Penetrate cell membrane to prevent intracellular ice formation; EG shows higher permeability and lower toxicity for oocytes/embryos [23]. |

| Non-Permeating Agents | Sucrose, Trehalose, Ficoll | Create osmotic gradient for dehydration; trehalose may offer superior glass-forming properties and membrane stabilization [26]. |

| Vitrification Containers | Cryo-loop, Open Pulled Straw, EM-grid, Cryotop | Enable ultra-rapid cooling; cryo-loop showed superior recovery rates for mouse embryos [27]. |

| Base Media | PBS with SSS, Synthetic serum substitute | Provide macromolecular support and osmotic stability during vitrification procedures [27] [22]. |

| Assessment Tools | Mito-Tracker dyes, ER-Tracker dyes, Hoechst stains | Evaluate subcellular organelle integrity and distribution post-warming; reveal mitochondrial and ER damage patterns [25]. |

| Pralnacasan | Pralnacasan, CAS:192755-52-5, MF:C26H29N5O7, MW:523.5 g/mol | Chemical Reagent |

| Pridefine | Pridefine, CAS:5370-41-2, MF:C19H21N, MW:263.4 g/mol | Chemical Reagent |

Membrane permeability characteristics fundamentally influence CPA exposure time optimization and damage mitigation in mouse embryo cryopreservation. The data and protocols presented demonstrate that later-stage embryos generally withstand vitrification better than earlier stages, and that ultra-fast vitrification methods significantly reduce CPA toxicity and osmotic stress. Implementation of stage-specific protocols with minimized, precise CPA exposure times can dramatically improve survival rates and developmental competence. These insights provide a foundation for developing refined, low-toxicity vitrification solutions that maximize preservation of cellular integrity and function.

Formulating and Applying Low-Toxicity Vitrification Solutions

Vitrification is a promising cryopreservation technique for complex biological specimens, including mouse embryos, as it prevents damaging ice formation by achieving a glassy state. However, this process requires high concentrations of cryoprotective agents (CPAs), which can exert significant chemical toxicity on cellular structures [28]. Rather than relying on single CPAs, contemporary cryopreservation research has demonstrated that using multi-CPA solutions can substantially reduce overall toxicity while maintaining vitrification capability [29].

This application note explores the strategic use of binary CPA combinations to achieve toxicity reduction through two primary mechanisms: mutual dilution (each CPA lowers the concentration of the others) and toxicity neutralization (one CPA counteracts the toxic effects of another) [29]. We provide quantitative data on effective CPA combinations, detailed experimental protocols for toxicity assessment, and specific methodologies for applying these mixtures to mouse embryo cryopreservation within the context of developing low-toxicity vitrification solutions.

Quantitative Data on CPA Mixture Toxicity

Key Binary Combinations Showing Toxicity Reduction

Table 1: Effective Binary CPA Combinations for Toxicity Reduction

| CPA Combination | Total Concentration | Observed Effect | Viability Outcome | Temperature | Cell Type | Citation |

|---|---|---|---|---|---|---|

| Formamide + Glycerol | 12 mol/kg | Toxicity neutralization | 97% viability (vs 20% with formamide alone) | 4°C | BPAEC | [30] |

| Formamide + Glycerol | 6 mol/kg | Significant toxicity decrease | Higher than single CPA solutions | Room Temperature | BPAEC | [31] |

| DMSO + 1,3-Propanediol | 6 mol/kg | Significant toxicity decrease | Higher than single CPA solutions | Room Temperature | BPAEC | [31] |

| 1,2-Propanediol + Diethylene Glycol | 6 mol/kg | Significant toxicity decrease | Higher than single CPA solutions | Room Temperature | BPAEC | [31] |

| 1,3-Propanediol + Diethylene Glycol | 6 mol/kg | Significant toxicity decrease | Higher than single CPA solutions | Room Temperature | BPAEC | [31] |

| Formamide + DMSO | Various | Toxicity neutralization | Reduced toxicity | Room Temperature | BPAEC | [29] |

Mathematical Modeling of CPA Mixture Toxicity

Advanced mathematical models have been developed to predict the toxicity of multi-CPA mixtures. These models account for both specific toxicity (direct effects of individual CPAs) and non-specific toxicity (overall effects on solution properties) [28]. The multi-CPA toxicity model incorporates interactions between common CPAs including glycerol, dimethyl sulfoxide (DMSO), propylene glycol, ethylene glycol, and formamide.

The general toxicity rate equation follows first-order kinetics:

dN/dt = -kN

Where N represents the number of viable cells, t is time, and k is the toxicity rate constant. For mixture prediction, the model uses data from single and binary CPA solutions to extrapolate to more complex mixtures [28].

Table 2: Optimized Vitrification Solution from Mathematical Modeling

| CPA Component | Concentration (molal) | Role in Mixture | Theoretical Basis |

|---|---|---|---|

| Glycerol | 7.4 | Primary cryoprotectant | Lower specific toxicity |

| DMSO | 1.4 | Synergistic component | Toxicity modulation |

| Formamide | 2.4 | Toxicity reduction | Interaction with glycerol |

This optimized mixture was identified by pairing the multi-CPA toxicity model with a vitrification/devitrification model, demonstrating the potential for mathematical optimization of vitrification solution composition [28].

Experimental Protocols

High-Throughput Toxicity Screening for CPA Mixtures

Diagram 1: High-throughput toxicity screening workflow for CPA mixtures.

Materials and Reagents

- Cells: Bovine Pulmonary Artery Endothelial Cells (BPAEC)

- CPAs: Formamide, glycerol, DMSO, 1,3-propanediol, 1,2-propanediol, diethylene glycol, ethylene glycol, propylene glycol

- Equipment: Hamilton Microlab STARlet automated liquid handling system

- Culture Media: Dulbecco's Modified Eagle Medium (DMEM) with 10% fetal bovine serum

- Viability Assay: PrestoBlue cell viability reagent

- Buffers: HEPES-buffered saline (HBS)

Procedure

CPA Stock Solution Preparation: Prepare individual CPA stock solutions at desired concentrations in HBS or appropriate buffer.

Automated Mixture Preparation: Program the liquid handler to create binary CPA mixtures in 96-well plates:

- Implement randomized plate layouts to minimize positional effects

- Include controls (cells without CPAs, single CPA solutions for comparison)

- Create concentration series for each binary combination

Cell Preparation and Seeding:

- Culture BPAEC under standard conditions (37°C, 5% CO₂)

- Seed cells in 96-well plates at optimal density (e.g., 10,000 cells/well)

- Allow cells to adhere overnight

CPA Exposure:

- Replace culture medium with CPA solutions using automated liquid handling

- Maintain consistent exposure times across experiments (e.g., 10-30 minutes)

- Conduct experiments at both room temperature and 4°C to assess temperature effects

CPA Removal:

- Perform multi-step removal using decreasing concentrations of CPAs

- Use automated liquid handling to ensure precision and reproducibility

Viability Assessment:

- Add PrestoBlue reagent to each well

- Incubate for predetermined time (typically 1-2 hours)

- Measure fluorescence using plate reader

- Calculate viability relative to control cells

Data Analysis:

- Normalize viability data to controls

- Compare binary mixture toxicity to constituent single CPAs

- Identify combinations showing significant toxicity reduction

Mouse Embryo Vitrification with Low-Toxicity CPA Mixtures

Diagram 2: Mouse embryo vitrification workflow using low-toxicity CPA mixtures.

Materials and Reagents

- Biological Material: Mouse morulae or 2-cell embryos

- Basal Medium: Modified phosphate-buffered saline (PB1 medium)

- Permeating CPAs: Ethylene glycol, glycerol, DMSO, formamide

- Non-Permeating CPA: Sucrose

- Polymer: Ficoll (for some formulations)

- Cryotop Devices or similar minimal volume tools

- Liquid nitrogen storage system

EDFS10/10a Vitrification Solution Formulation

Developed specifically for equilibrium vitrification of mouse embryos with minimal toxicity:

- Total Permeating CPA Concentration: 20% (v/v)

- Typically 10% ethylene glycol + 10% DMSO

- Sucrose Concentration: 0.4 M

- Base Medium: Modified PB1

This low-CPA concentration formulation significantly reduces toxicity compared to traditional vitrification solutions like EFS35c while maintaining effective vitrification [32].

Procedure

Embryo Collection:

- Collect morulae or 2-cell embryos from superovulated mice

- Select only high-quality embryos with uniform blastomeres and intact zonae pellucidae

CPA Equilibration:

- Expose embryos to EDFS10/10a solution at room temperature for 10 minutes

- Observe embryonic dehydration and re-expansion during equilibration

Vitrification Process:

- Load 5-6 embryos in minimal volume (<1 μL) onto Cryotop device

- Immediately plunge into liquid nitrogen

- Store in liquid nitrogen for desired duration

Warning and CPA Removal:

- Rapidly warm Cryotop in 20°C water bath for 5 seconds

- Transfer embryos through decreasing concentrations of sucrose solutions (0.5 M, 0.25 M) for 5 minutes each

- Rinse in base medium

Viability Assessment:

- Culture embryos in Hypermedium under oil at 37°C, 6% CO₂

- Assess survival by morphological appearance and re-expansion

- Evaluate developmental competence by progression to blastocyst stage

- For comprehensive assessment, transfer embryos to recipients to measure live birth rates

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for CPA Mixture Studies

| Reagent/Category | Specific Examples | Function/Application | Notes |

|---|---|---|---|

| Permeating CPAs | Ethylene glycol, glycerol, DMSO, propylene glycol, formamide | Penetrate cell membranes to prevent intracellular ice formation | Formamide shows notable toxicity neutralization with glycerol and DMSO [30] [29] |

| Non-Permeating CPAs | Sucrose, Ficoll, diethylene glycol | Provide extracellular protection, increase viscosity | Sucrose is essential in equilibrium vitrification solutions [32] |

| Cell Culture Systems | BPAEC, mouse embryos | Toxicity screening models | BPAEC provides high-throughput capability; mouse embryos offer clinical relevance |

| Viability Assays | PrestoBlue, MTT assay | Quantify cellular toxicity | PrestoBlue enables high-throughput screening [29] |

| Automated Platforms | Hamilton Microlab STARlet | Precision liquid handling for mixture preparation | Critical for reproducibility in mixture studies [29] |

| Vitrification Devices | Cryotop, mini straws | Minimal volume containment for ultra-rapid cooling | Cryotop enables high cooling/warming rates [33] |

| Mathematical Models | Multi-CPA toxicity model, vitrification/devitrification models | Predict toxicity and optimize mixtures | Combines specific toxicity, non-specific toxicity, and CPA interactions [28] |

| Neoeriocitrin | Neoeriocitrin, CAS:13241-32-2, MF:C27H32O15, MW:596.5 g/mol | Chemical Reagent | Bench Chemicals |

| Netropsin | Netropsin, CAS:1438-30-8, MF:C18H26N10O3, MW:430.5 g/mol | Chemical Reagent | Bench Chemicals |

Mechanisms of Toxicity Reduction in CPA Mixtures

Toxicity Neutralization Phenomenon

Toxicity neutralization occurs when the addition of a second CPA eliminates or significantly reduces the toxic effects of the first CPA. The most documented example is the neutralization of formamide toxicity by glycerol or DMSO [30] [29]. When formamide at 6 mol/kg alone resulted in only 20% viability, the addition of 6 mol/kg glycerol created a mixture with total 12 mol/kg concentration that yielded 97% viability - effectively eliminating formamide's toxicity while maintaining cryoprotective potential.

Molecular Interactions

The molecular mechanisms behind toxicity reduction in CPA mixtures may involve:

- CPA Complex Formation: Intermolecular interactions between different CPAs that reduce their individual toxicities while maintaining cryoprotective function [28]

- Membrane Stabilization: Complementary effects on membrane structure that preserve integrity

- Reduced Osmotic Stress: Balanced permeation rates that minimize volume excursions

- Metabolic Protection: Preservation of mitochondrial function and reduction of oxidative stress

Application to Mouse Embryo Cryopreservation

The development of low-toxicity CPA mixtures has direct applications in mouse embryo cryopreservation for reproductive technologies and biomedical research. The EDFS10/10a solution, containing reduced CPA concentrations (total 20% permeating CPAs + 0.4 M sucrose), has demonstrated excellent results with 2-cell mouse embryos [32].

This equilibrium vitrification approach provides several advantages:

- Enables vitrification with minimal supercooling

- Allows transportation on dry ice rather than liquid nitrogen

- Reduces CPA toxicity while maintaining high survival rates

- Simplifies the cooling/warming process without needing programmable freezers

Using this approach, mouse morulae vitrified in EFS solution (containing 40% ethylene glycol + 30% Ficoll + 0.5 M sucrose) for 2-5 minutes showed 97-98% development in culture and 51% developed to live young after transfer [12].

Strategic formulation of binary CPA mixtures presents a powerful approach for reducing toxicity in vitrification solutions for mouse embryo cryopreservation. The combination of high-throughput screening, mathematical modeling, and empirical validation has identified specific synergistic pairs - particularly formamide/glycerol and formamide/DMSO - that significantly improve cellular viability while maintaining cryoprotective efficacy.

The protocols and data presented herein provide researchers with practical tools for implementing these advanced CPA mixtures in their cryopreservation workflow, advancing the goal of developing reliable, low-toxicity vitrification methods for sensitive biological specimens.

The cryopreservation of biological samples, from single cells to complex tissues, is a cornerstone of modern biomedical research, assisted reproductive technologies, and biobanking. The success of these procedures hinges on cryoprotective agents (CPAs), which mitigate freezing damage but often introduce inherent chemical toxicity that can compromise sample viability. This challenge has catalyzed the development of low-toxicity vitrification solutions, designed to enable ice-free preservation while maintaining cellular function post-thaw. For researchers focusing on mouse embryo cryopreservation, optimizing CPA cocktails to minimize toxicity is particularly critical, as it directly impacts subsequent embryonic development and the reliability of experimental or breeding outcomes.

Traditional penetrating cryoprotectants like dimethyl sulfoxide (DMSO), propylene glycol (PROH), and ethylene glycol (EG) have been widely used for decades. However, side-by-side toxicity comparisons reveal significant differences in their effects on cellular survival and function [34]. The drive towards lower toxicity formulations has led to innovations such as the VEG cocktail (Vitrification Solution with Ethylene Glycol), which was specifically designed to reduce the toxic burden of previous standards like VS55 [35]. This overview details the composition, efficacy, and application of these advanced, low-toxicity solutions, providing a structured guide for their implementation in mouse embryo research.

Comparative Analysis of Cryoprotectants

Toxicity Profiles of Conventional Cryoprotectants

The toxicity of a cryoprotectant is a function of its chemical nature, concentration, exposure time, and temperature. Understanding the relative toxicity of conventional agents is the first step in formulating safer, more effective cocktails.

Table 1: Comparative Toxicity of Common Penetrating Cryoprotectants on Mouse Oocytes/Embryos

| Cryoprotectant | Recommended Concentration | Exposure Conditions | Key Toxicity Findings | Developmental Outcome |

|---|---|---|---|---|

| Ethylene Glycol (EG) | 1.5 M | 15 min, Room Temp | Minimal toxicity; no adverse effects on survival, fertilization, or development [34]. | High blastocyst formation and hatching rates, particularly with vitrification protocols [36]. |

| Dimethyl Sulfoxide (DMSO) | 1.5 M | 15 min, Room Temp | Low toxicity; no significant adverse effects on key criteria [34]. | Effective with slow-freezing; less effective than EG in some vitrification protocols [36]. |

| Propylene Glycol (PROH) | 1.5 M | 15 min, Room Temp | High toxicity; significant oocyte degeneration (54.2%) and parthenogenetic activation (16%) [34]. | Lower survival and blastocyst formation rates; toxicity exacerbated at 37°C [34]. |

| Glycerol (G) | 1.0 - 1.5 M | Varies by protocol | Less effective for rapid freezing of embryos; relatively weak penetrability [37]. | Lower success rates compared to EG and PROH in some studies [36]. |

The data indicate that ethylene glycol consistently demonstrates a favorable toxicity profile, making it a preferred base for novel low-toxicity formulations. In contrast, PROH exhibits marked toxicity, which can be mitigated by using it in combination with other CPAs at lower concentrations [34].

Novel Low-Toxicity Formulations: The Case of VEG

The pursuit of lower toxicity has led to the development of specialized CPA cocktails for challenging applications like organ vitrification. A key advancement is the VEG solution.

Table 2: Composition and Features of VS55 vs. VEG Cryoprotectant Cocktails

| Characteristic | VS55 | VEG |

|---|---|---|

| Total Molarity | ~8.4 M | >8 M (Vitrification-relevant) |

| Primary Composition | DMSO, Formamide, PROH | Ethylene Glycol (replaces PROH) |

| Carrier Solution | Euro-Collins (EC) | Compatible with multiple (e.g., Celsior) |

| Reported Toxicity | Higher LDH release in rat hearts [35] | Reduced toxicity (lower LDH release) [35] |

| Key Advantage | Pioneering vitrification solution for organs | Improved biocompatibility and reduced chemical toxicity |

VEG was developed by replacing the more toxic propylene glycol (PROH) in the VS55 formula with ethylene glycol (EG). This substitution is grounded in the established lower toxicity of EG, as shown in Table 1. In direct screening studies on rat hearts, VEG in a Celsior carrier solution resulted in significantly lower lactate dehydrogenase (LDH) release—a marker of cell damage—compared to VS55, confirming its reduced cytotoxic profile [35]. While functional recovery of whole hearts was similar between the two cocktails, the reduced enzymatic leakage strongly supports VEG as a less toxic alternative for vitrification at high concentrations [35].

Essential Protocols for Mouse Embryo Cryopreservation

Ethylene Glycol-Based Vitrification for Mouse Embryos

The following protocol, optimized at the RIKEN BioResource Center, utilizes ethylene glycol as the primary CPA for its low toxicity and effectiveness with mouse embryos at room temperature [38].

Research Reagent Solutions

- Vitrification Solution: 30-40% (v/v) Ethylene Glycol, 0.5-1.0 M Sucrose, and a high molecular weight polymer like Ficoll (e.g., 10-20%) in a base medium (e.g., PBS with fetal bovine serum) [38].

- Base Medium: Phosphate-buffered saline (PBS) supplemented with 10-20% fetal bovine serum (FBS) or synthetic serum substitute.

- Equilibration Solution: A lower concentration (e.g., 7.5-10%) of ethylene glycol in base medium.

- Warming/Thawing Solution: 1.0 M Sucrose in base medium.

- Dilution Solutions: Stepwise sucrose solutions (e.g., 0.5 M, 0.25 M) in base medium.

Detailed Protocol

- Preparation: Place multiple drops of Vitrification Solution, Equilibration Solution, and base medium on a culture dish lid. Use cryotubes pre-warmed to room temperature.

- Equilibration: Transfer 10-20 embryos into the Equilibration Solution for 5-15 minutes at room temperature (approx. 23-25°C). This partial dehydration and CPA loading step reduces osmotic shock.

- Vitrification: a. Move the embryos from the Equilibration Solution to the concentrated Vitrification Solution. b. Quickly aspirate the embryos in a minimal volume (≤2 µl) and place them as a droplet on the inner wall of the cryotube. The entire process from entering the Vitrification Solution to sealing the tube should not exceed 60-90 seconds. c. Immediately plunge the sealed cryotube directly into liquid nitrogen for storage.

- Warming (Liquefaction): a. Warm the cryotube in air for a few seconds (optional, protocol-dependent). b. Rapidly open the tube and add pre-warmed (37°C) 1.0 M Sucrose (Warming) Solution. c. Gently mix and transfer the entire contents to a culture dish.

- Dilution and Rehydration: a. After 1-2 minutes in the 1.0 M Sucrose solution, transfer the embryos through a series of decreasing sucrose concentrations (e.g., 0.5 M, 0.25 M) for 5-10 minutes each at room temperature. b. Finally, wash the embryos twice in base medium or culture medium before transferring to a culture dish for recovery and assessment.

Ultra-Fast Vitrification to Minimize Toxicity

A complementary strategy to reduce CPA toxicity is to minimize exposure time. The Ultra-Fast Vitrification (UF-VIT) protocol achieves this by bypassing the traditional equilibration step, thereby reducing both chemical and osmotic stress [25].

Workflow: Ultra-Fast vs. Conventional Vitrification

Key Experimental Steps for UF-VIT:

- Minimal Volume Handling: Prior to CPA addition, remove the surrounding medium to minimize the volume of water that must be displaced, thus speeding up dehydration [25].

- Direct VS Exposure: Transfer the embryos directly into the Vitrification Solution, omitting or drastically reducing the time in a lower-concentration Equilibration Solution. The exposure time in the VS is critically short (e.g., less than 30-60 seconds) [25].

- Rapid Cooling and Warming: Proceed with rapid plunging into liquid nitrogen and subsequent warming as described in the standard protocol, ensuring the warming rate is sufficiently high to prevent devitrification.

Evidence of Efficacy: Studies on mouse oocytes show that UF-VIT results in significantly better preservation of mitochondrial distribution and membrane potential, as well as higher blastocyst formation rates, compared to conventional vitrification (C-VIT) [25]. This demonstrates that minimizing CPA exposure time is a potent strategy for enhancing post-thaw viability.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for Low-Toxicity Cryopreservation

| Reagent/Material | Function/Description | Example Use Case |

|---|---|---|

| Ethylene Glycol (EG) | Low-toxicity penetrating CPA; reduces ice formation and osmotic stress [38] [34]. | Primary cryoprotectant in VEG cocktail and mouse embryo vitrification [38] [35]. |

| Sucrose | Non-penetrating osmolyte; aids dehydration and prevents osmotic shock during dilution [38]. | Standard component of vitrification and warming/dilution solutions [38]. |

| Ficoll PM-70 | High molecular weight polymer; increases solution viscosity and helps prevent devitrification [38]. | Added to vitrification solution to promote a stable glassy state. |

| Celsior Carrier Solution | Balanced salt solution; designed for organ preservation; shows superior results for heart CPA perfusion [35]. | Carrier solution for VEG and VS55 in organ vitrification studies [35]. |

| DMSO | Traditional penetrating CPA; effective but with higher toxicity concerns at high concentrations/vs. EG [34] [35]. | Component of VS55 cocktail; often used in slow-freezing protocols. |

| Propanediol (PROH) | Penetrating CPA; can exhibit high toxicity to oocytes/embryos [34]. | Use with caution; often combined with other CPAs at lower concentrations to mitigate toxicity [34]. |

| Pachypodol | Pachypodol, CAS:33708-72-4, MF:C18H16O7, MW:344.3 g/mol | Chemical Reagent |

| Piperitenone | Piperitenone|Natural Monoterpene Ketone for Research | High-purity Piperitenone, a mint-scented monoterpene for antimicrobial and antifungal research applications. For Research Use Only. Not for human consumption. |

The advancement of cryopreservation science is intrinsically linked to the development of safer, more effective cryoprotective formulations. For researchers in mouse embryo cryopreservation, the evidence strongly supports a shift towards ethylene glycol-based solutions and protocols like ultra-fast vitrification that collectively address the dual challenges of chemical and osmotic toxicity. The VEG cocktail exemplifies this progress, demonstrating that strategic reformulation can significantly reduce cytotoxic damage even at the high concentrations required for vitrification. By adopting these low-toxicity solutions and optimized protocols, scientists can enhance the viability and developmental potential of cryopreserved mouse embryos, thereby improving the reliability and efficiency of this indispensable biotechnological tool.

Cryopreservation is a cornerstone technique for the archiving and distribution of genetically engineered mouse strains, vital for biomedical research. Vitrification, a rapid cooling process that solidifies cells into a glass-like state without forming damaging ice crystals, has become the preferred method over traditional slow-freezing [39]. This protocol details a low-toxicity vitrification procedure for mouse embryos, utilizing a reduced concentration of cryoprotectants to minimize chemical toxicity and osmotic stress, thereby enhancing embryo survival and developmental potential post-warming [32]. This method is designed for researchers aiming to establish robust and efficient embryo banks.

Principle of Low-Toxicity Equilibrium Vitrification

Conventional vitrification relies on high concentrations of cryoprotectant agents (CPAs) and ultra-rapid cooling to prevent ice crystallization. However, high CPA concentrations pose risks of chemical toxicity and osmotic shock to embryos [39]. The low-toxicity equilibrium vitrification method achieves a near-equilibrium state by using a solution containing lower concentrations of both permeating and non-permeating cryoprotectants [32]. The high osmolality of the solution, primarily contributed by a non-permeating CPA like sucrose, promotes rapid dehydration of the embryo. This allows for vitrification with less permeating CPA, reducing associated toxicity. Embryos treated this way can be cooled relatively slowly and are less susceptible to damage during the warming process [32].

Research Reagent Solutions and Materials

Key Research Reagents

| Reagent | Function in Protocol | Example Formulation |

|---|---|---|

| Permeating Cryoprotectants (CPAs) | Penetrate the cell membrane, protecting from intracellular ice formation. | Ethylene Glycol (EG), Dimethyl Sulfoxide (DMSO), Propylene Glycol (PG) [40] [39]. |

| Non-Permeating Cryoprotectants | Create an osmotic gradient, drawing water out of the cell to aid dehydration. | Sucrose, Ficoll, Trehalose [40] [39]. |

| Base Medium | Foundation for preparing CPA solutions, providing nutrients and pH buffer. | Modified M2 medium [40]. |

| Osmotic Buffer | Used during warming to remove CPAs gradually and rehydrate the embryo safely. | 0.25 M Sucrose in M2 [40]. |

| In Vitro Culture Medium | Supports embryo development after warming to assess viability. | KSOM or M16 medium [40]. |

Equipment and Supplies

- Stereo-microscope for embryo handling and assessment.

- 37°C, 5% CO2 humidified incubator for embryo culture.

- Liquid nitrogen tank and Dewar for storage and processing.

- Vitrification device: Straws [41] or spatulas [42] are commonly used.

- General lab equipment: Petri dishes, pipettors, forceps, cryogenic vials [40].

Detailed Step-by-Step Protocol

Preparation of Solutions

Low-Toxicity Vitrification Solution (e.g., EDFS10/10a formulation) [32]:

- This solution typically contains a total of 20% (v/v) permeating cryoprotectants (e.g., a combination of EG and DMSO) and 0.4 M sucrose in a base medium.

- Prepare fresh and equilibrate to room temperature (25°C) before use.

Osmotic Buffer (Thawing Solution) [40]:

- 0.25 M Sucrose in M2 medium. Prepare aliquots and store at -80°C. Warm to 37°C before use.

In Vitro Culture (IVC) Medium [40]:

- Prepare drops of KSOM or M16 medium under embryo-tested mineral oil in a culture dish.

- Equilibrate in a 5% CO2 incubator at 37°C overnight or for at least one hour before warming embryos.

Equilibration and Vitrification Procedure

Embryo Collection: Collect 2-cell stage mouse embryos in M2 medium [42].

Exposure to Vitrification Solution: Using a stereomicroscope, transfer the embryos directly into the pre-equilibrated low-toxicity vitrification solution (e.g., EDFS10/10a) at room temperature [32].

Equilibration Incubation: Leave the embryos in the vitrification solution for 10 minutes at room temperature. During this period, observe initial osmotic shrinkage as water leaves the cells, followed by a slight return to volume as CPAs permeate [32].

Loading and Sealing: After equilibration, quickly load a group of embryos (up to 50) in a minimal volume of solution (e.g., 5 µl) onto a vitrification straw or spatula [40].

Vitrification: Immediately after loading, plunge the device directly into liquid nitrogen. The entire content should solidify into a glassy state within seconds. Ensure the cooling rate is extremely high (>250,000°C/min if using specialized devices) to prevent ice crystal formation [43] [32].

Storage: Transfer the vitrified samples to a pre-cooled cryogenic vial or sealed straw system and place them into a labeled position within a liquid nitrogen storage tank for long-term preservation [40].

Warming and Recovery Procedure

Prepare Thawing Environment: Have a petri dish ready with a 200 µL drop of warm (37°C) 0.25 M sucrose solution. Pre-warm the IVC dish in the incubator [40].

Rapid Warming and CPA Removal:

- Remove the straw/spatula from liquid nitrogen and open the container.

- Quickly add 0.9 mL of warm 0.25 M sucrose solution to the vial or directly expel the contents into the sucrose drop. Gently pipette to mix and thaw the sample completely [40].

- Transfer the embryos into the 0.25 M sucrose drop and incubate at room temperature for 10 minutes [40].

Washing and Rehydration: Wash the embryos twice by transferring them sequentially through two drops of pre-warmed base medium (M2) to remove residual sucrose and CPAs [40].

Post-Warm Culture: Finally, transfer the embryos to the pre-equilibrated KSOM or M16 culture drops. Return the culture dish to the 37°C, 5% CO2 incubator [40].

Assessment of Survival: Assess embryo survival and developmental competence after a few hours of culture or proceed directly to embryo transfer into pseudopregnant female mice.

Expected Results and Performance Data

When performed correctly, this low-toxicity equilibrium vitrification protocol yields high survival and development rates. The table below summarizes expected outcomes based on published research.

Table: Expected Embryo Development Outcomes Post-Vitrification

| Strain / Embryo Type | Vitrification Solution | Survival / Blastocyst Development Rate | Key Findings |

|---|---|---|---|

| ICR (2-cell) | EDFS10/10a (Low CPA) | >90% development to blastocyst [32] | No significant difference from fresh control embryos. |

| C57BL/6 (2-cell) | EDFS10/10a (Low CPA) | ~90% development to blastocyst [32] | High tolerance for the low-CPA formula. |

| Ccr2, Ccr5, Tlr6 GM strains | Tsang and Chow technique | 52.8% - 66.7% development [42] | No significant difference from non-vitrified controls for these specific strains. |

| Various GM strains | DAP213 | Effective archiving demonstrated [40] | Protocol is practical for large-scale banking of multiple strains. |

Troubleshooting Guide

| Problem | Potential Cause | Solution |

|---|---|---|

| Low survival post-warm | Intracellular ice formation | Ensure rapid plunging into LN2; check that sample volume is minimal [43]. |

| Embryos lysed during warming | Osmotic shock during CPA removal | Ensure the sucrose thawing solution is warm (37°C) and that incubation times are precise [40]. |

| Low development to blastocyst | CPA toxicity | Strictly adhere to room temperature operation and exposure times; prepare fresh CPA solutions [32]. |

| Cracks in vitrified droplet | Fracture damage | Handle samples with care during storage and transport under LN2; avoid rapid temperature shifts [32]. |

Ultra-fast vitrification (UF-VIT) represents a significant methodological advancement in the field of oocyte cryopreservation. This technique is specifically designed to mitigate two primary sources of cellular injury: the toxicity of high-concentration cryoprotective agents (CPAs) and the osmotic stress inherent in conventional vitrification (C-VIT) protocols. By substantially reducing exposure time to equilibration solutions, UF-VIT minimizes the amplitude of cell contraction and expansion, thereby preserving the structural and functional integrity of critical intracellular organelles [44]. Within the broader context of developing low-toxicity vitrification solutions for mouse embryo cryopreservation research, UF-VIT offers a promising paradigm that balances the competing demands of effective cryoprotection and minimal chemical/osmotic damage.

Key Principles and Rationale

The fundamental principle of UF-VIT involves preserving oocytes with minimal fluid volume immediately before introducing CPAs, thereby effectively bypassing the prolonged osmotic equilibrium phase typical of conventional protocols [44]. This approach leverages rapid cooling rates to achieve a glass-like state while permitting the use of lower CPA concentrations, thus combining the benefits of both slow-freezing and vitrification techniques [43].

The theoretical foundation rests upon the critical relationship between cooling rate and the required CPA concentration for successful vitrification. As cooling rates increase, the minimum CPA concentration needed to prevent ice crystal formation decreases proportionally [43]. UF-VIT capitalizes on this principle by utilizing extremely high cooling rates (up to 250,000°C/min in some systems) to enable vitrification with reduced CPA concentrations, thereby minimizing chemical toxicity while still preventing intracellular ice formation [43].

Mechanism of Reduced Osmotic Stress in UF-VIT

Comparative Performance Data

Organelle Integrity and Developmental Outcomes