Optimizing Proteinase K Digestion Time: A Complete Guide for Reliable Nucleic Acid Extraction

This article provides a comprehensive guide for researchers and drug development professionals on optimizing Proteinase K digestion time to maximize nucleic acid yield and purity.

Optimizing Proteinase K Digestion Time: A Complete Guide for Reliable Nucleic Acid Extraction

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on optimizing Proteinase K digestion time to maximize nucleic acid yield and purity. It covers the foundational principles of Proteinase K activity, details methodological approaches for diverse sample types including tissues, blood, and sputum, and offers advanced troubleshooting for common pitfalls. A comparative analysis validates its performance against alternative methods, presenting a holistic framework for refining sample preparation protocols in molecular biology, clinical diagnostics, and biopharmaceutical research.

Understanding Proteinase K: Core Principles for Effective Digestion

What is Proteinase K? Defining the Serine Protease and Its Broad Substrate Specificity

Proteinase K is a broad-spectrum serine protease isolated from the fungus Engyodontium album [1]. It belongs to the subtilisin family (Peptidase family S8) and is characterized by its exceptional stability and ability to hydrolyze a wide range of peptide bonds, particularly those adjacent to the carboxyl group of aliphatic and aromatic amino acids [1] [2]. Its name originates from its notable ability to digest keratin, a tough structural protein [1]. In molecular biology, its primary application is the digestion of proteins and the removal of contaminating nucleases during the purification of nucleic acids (DNA and RNA), thereby ensuring the integrity of the isolated genetic material [1] [3].

This technical resource is framed within ongoing research to optimize Proteinase K digestion times, a critical variable influencing yield and purity in downstream applications. The following sections provide detailed protocols, troubleshooting guides, and reagent information to support robust experimental design.

Enzyme Properties & Mechanism

Biochemical and Catalytic Profile

Proteinase K is a single polypeptide chain of approximately 279 amino acids with a molecular weight of about 28.9 kDa [1] [4] [2]. Its catalytic mechanism relies on a classic serine protease triad composed of Asp39, His69, and Ser224 [2].

The enzyme exhibits broad substrate specificity. While it shows a preference for peptide bonds adjacent to hydrophobic and aromatic amino acids, its exact specificity at sub-sites from P2 to P3' has been shown to be nearly identical to that of subtilisin Carlsberg, despite relatively low sequence identity [5].

Table 1: Key Biochemical Properties of Proteinase K

| Property | Description |

|---|---|

| Type | Serine protease (Subtilisin family, S8) [1] |

| Source | Engyodontium album (formerly Tritirachium album) [1] [6] |

| Molecular Weight | ~28.9 kDa [1] [4] |

| Catalytic Triad | Asp39, His69, Ser224 [2] |

| Specificity | Broad; cleaves after aliphatic, aromatic, and other hydrophobic amino acids [1] [5] |

Stability and Activators

A key feature of Proteinase K is its remarkable stability under harsh conditions, which is leveraged in many nucleic acid purification protocols.

- pH Stability: The enzyme remains active over a very wide pH range of 4.0 to 12.5, with an optimal activity between pH 7.5 and 9.0 [1] [7] [3].

- Temperature Stability: It is active from 20–65°C [6] [3]. While it can function at room temperature, its optimal activity lies between 50–65°C [7] [4] [3]. It is rapidly inactivated by heating to 95°C for 10 minutes [4].

- Cofactors: Calcium ions (Ca²⁺) bind to two sites on the enzyme, significantly contributing to its structural stability and resistance to thermal denaturation and autolysis [1] [4] [2]. However, calcium is not required for catalytic activity [6].

- Activators: The enzyme's activity against native proteins is significantly enhanced in the presence of denaturants like SDS (0.5-2%) and urea (up to 4 M) [1] [6]. These denaturants unfold protein substrates, making cleavage sites more accessible to the protease [1].

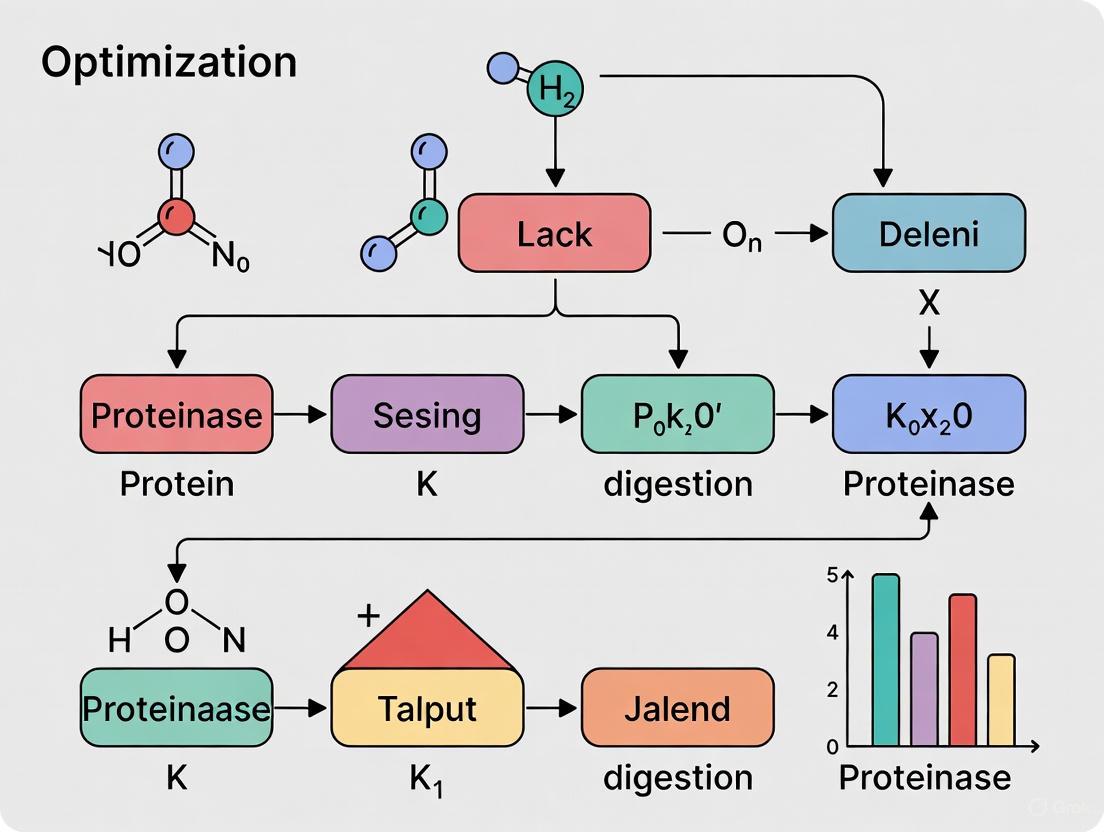

Diagram 1: Summary of key properties and reaction conditions for Proteinase K.

Experimental Protocols & Optimization

Standard Stock Solution Preparation

A common stock concentration is 20 mg/mL [2].

- Weigh the desired amount of Proteinase K powder.

- Dissolve in an appropriate solvent. Common choices include:

- Mix well by vortexing or pipetting.

- Aliquot and store at -20°C or below to preserve activity [7] [4].

General DNA Extraction Protocol with Digestion Optimization

This protocol highlights how to incorporate and optimize Proteinase K digestion for genomic DNA isolation.

- Lysis: Suspend cell pellet or tissue in a lysis buffer (e.g., 100 mM Tris-HCl, 50 mM EDTA, 0.5% SDS). The EDTA chelates Mg²⁺, inhibiting DNases, while SDS denatures proteins and membranes [1].

- Digestion: Add Proteinase K to a final working concentration of 50–100 µg/mL [2]. Incubate with gentle agitation. Critical: Optimize digestion time and temperature (see Table 2).

- Inactivation: After digestion, heat the sample to 95°C for 10 minutes to inactivate Proteinase K [4]. Alternatively, protease inhibitors like PMSF or AEBSF can be used for permanent inactivation [4].

- Purification: Proceed with standard phenol-chloroform extraction and alcohol precipitation, or use a commercial nucleic acid purification kit.

Table 2: Optimizing Digestion Conditions for Different Sample Types

| Sample Type | Recommended [Proteinase K] | Temperature | Time (Guideline) | Optimization Notes |

|---|---|---|---|---|

| Cultured Mammalian Cells | 50–100 µg/mL [2] | 50–56°C | 1–3 hours | Standardized protocol; time can often be minimized. |

| Tissue Samples | 100–200 µg/mL | 56°C | 3 hours to overnight | Fixed tissues or tough tissues (e.g., muscle) require longer digestion. |

| Forensic Samples (e.g., Bone, Hair) | Recombinant, high-activity grades [8] | 56°C | 30 minutes [8] | Newer high-activity formulations can reduce time from 90 to 30 minutes. |

| Blood | As per kit/manual | 37–56°C | 30 min - 2 hours [7] | Higher temperatures may cause hemoglobin release, which can inhibit PCR. |

Troubleshooting Guide (FAQs)

Q1: How do I completely inactivate Proteinase K? The most common method is heat inactivation at 95°C for 10 minutes [4]. However, note that this may not lead to 100% inactivation, and a small amount of residual activity might remain [4]. For complete and permanent inactivation, especially in sensitive downstream applications, use serine protease inhibitors like PMSF (phenylmethylsulfonyl fluoride) or AEBSF [1] [4].

Q2: Why is my nucleic acid yield low or degraded after Proteinase K treatment? This could be due to over-digestion [7]. Using too much enzyme or digesting for too long can lead to the degradation of your target nucleic acids or the release of inhibitors from the sample (e.g., heme from blood) [7]. Solution: Titrate the enzyme amount and duration for your specific sample type rather than using a fixed excess.

Q3: Does EDTA inactivate Proteinase K? No. While EDTA chelates calcium ions and thereby reduces the enzyme's stability, it does not directly inhibit its proteolytic activity [1] [4]. Proteinase K remains active in buffers containing EDTA, which is beneficial for inactitating metal-ion dependent nucleases [1] [6].

Q4: The enzyme doesn't seem to be working. What could be wrong? Consider common inhibitors:

- Serine Protease Inhibitors: Check if your buffers contain PMSF, AEBSF, or DFP [1] [7].

- Loss of Activity: Improper storage or repeated freeze-thaw cycles can degrade the enzyme. Always store at -20°C or below and use aliquots [7] [4].

- Incompatible Reagents: High concentrations of certain detergents (e.g., Triton X-100, Tween 20) can inhibit activity [7].

Q5: Why are SDS and urea sometimes called "activators" of Proteinase K? These denaturants unfold native protein structures, making the peptide bonds more accessible for cleavage by the protease. This enhances the digestion of native proteins. Conversely, when using small peptide substrates, these denaturants can inhibit the enzyme [1].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Proteinase K-based Experiments

| Reagent / Material | Function / Role | Key Considerations |

|---|---|---|

| Proteinase K (Lyophilized Powder) | Stable, long-term storage (up to 2 years at -20°C) [4]. Cost-effective for preparing stock solutions. | Dominates the market (61% share in 2024) due to stability [8]. |

| Proteinase K (Liquid Solution) | Ready-to-use; ideal for automated high-throughput workflows [8]. | Gaining traction; convenient but may have a shorter shelf-life [8]. |

| SDS (Sodium Dodecyl Sulfate) | Denaturant and activator. Disrupts membranes and unfolds proteins, enhancing Proteinase K digestion efficiency [1] [4]. | High concentrations (>2%) can denature and inactivate Proteinase K [7]. |

| EDTA (Ethylenediaminetetraacetic acid) | Chelating agent. Binds Mg²⁺ to inhibit DNases, essential for protecting nucleic acids during extraction [1]. | Reduces stability of Proteinase K by removing Ca²⁺, but activity remains [1] [4]. |

| Tris-HCl Buffer (pH 8.0) | Provides optimal alkaline pH environment for enzyme activity [1] [7]. | A common buffer base for stock solutions and digestion reactions [7]. |

| Calcium Chloride (CaCl₂) | Stabilizing cofactor. Added to stock solutions to maintain enzyme stability over time [4] [2]. | Not required for catalysis, but crucial for preventing autolysis and enhancing heat resistance [1] [2]. |

| PMSF (PMSF) | Serine protease inhibitor. Used for permanent and complete inactivation of Proteinase K after digestion [1] [4]. | Highly toxic and unstable in aqueous solution; must be used fresh [1]. |

Diagram 2: A standard workflow for using Proteinase K in nucleic acid purification, highlighting key reagents and steps.

Proteinase K is a broad-spectrum serine protease that breaks down proteins by hydrolyzing peptide bonds [9]. Discovered in 1974 in extracts of the fungus Engyodontium album (formerly Tritirachium album), this enzyme exhibits remarkable stability and can digest a wide variety of proteins, including those resistant to other proteases [1] [10]. The enzyme derives its name from its ability to digest native keratin, the primary component of hair [10]. In molecular biology applications, Proteinase K is particularly valued for its ability to inactivate nucleases that could otherwise degrade DNA and RNA during purification processes, thereby protecting the integrity of nucleic acids for downstream applications [9] [11].

Molecular Mechanism of Peptide Bond Cleavage

Enzymatic Classification and Active Site

Proteinase K belongs to the peptidase family S8 (subtilisin family) and functions as a serine protease due to the presence of a catalytic serine residue in its active site [1] [10]. Unlike many mammalian serine proteases, Proteinase K does not require a zymogen activation step and is active upon production [1]. The molecular weight of Proteinase K is approximately 28,900 daltons (28.9 kDa) [1] [10].

Stepwise Mechanism of Action

The cleavage of peptide bonds by Proteinase K follows a multi-step catalytic mechanism:

Binding: Proteinase K first binds to protein or nucleic acid substrates through non-specific hydrophobic interactions [9]. The enzyme exhibits a preference for cleaving peptide bonds adjacent to the carboxyl group of aliphatic and aromatic amino acids with blocked alpha amino groups [1] [10].

Activation: Once bound, the enzyme undergoes an activation step where a catalytic serine residue is activated by a histidine residue and a water molecule, forming an active site capable of cleaving peptide bonds [9].

Cleavage: The active site of Proteinase K cleaves the peptide bond on the carboxylic acid side of hydrophobic amino acid residues (aliphatic and aromatic) [9]. The enzyme can also cleave peptide bonds on the amide side of glycine residues [9].

Product Release: After cleavage, the resulting peptide fragments are released from the enzyme, allowing the catalytic cycle to repeat [9].

The following diagram illustrates this catalytic mechanism:

Cofactors and Stability

Proteinase K possesses two binding sites for calcium ions (Ca²⁺) that are located close to the active center but are not directly involved in the catalytic mechanism [1] [10]. While calcium ions do not affect the enzyme's catalytic activity, they significantly contribute to its structural stability [1]. Upon removal of calcium ions (e.g., by chelating agents like EDTA), the enzyme's stability decreases but substantial proteolytic activity remains—a feature particularly useful in nucleic acid purification protocols where DNases must be inactivated without impairing Proteinase K function [1].

Optimal Working Conditions and Buffer Compatibility

Environmental Factors Influencing Activity

Proteinase K exhibits remarkable stability under various conditions that would denature many other enzymes:

pH Stability: Proteinase K remains active across a broad pH range of 4.0-12.0, with an optimum at pH 8.0 [1] [11]. The enzyme retains full activity for several hours at pH 6.5-9.5 [11].

Temperature Range: The enzyme functions effectively from 37°C to 60°C, with elevated temperatures (50-60°C) significantly increasing its activity [9] [1] [10]. Proteinase K can be inactivated by heating at temperatures above 65°C or by extreme pH changes [10].

Denaturant Tolerance: Unlike most enzymes, Proteinase K remains active in the presence of denaturing agents such as SDS (0.5-1%), urea (4M), and guanidinium salts [9] [1] [11]. These denaturants actually enhance its activity against native proteins by unfolding substrate proteins and making cleavage sites more accessible [1] [10].

Buffer Composition and Relative Activity

The activity of Proteinase K varies significantly depending on buffer composition, as demonstrated by the following experimental data:

Table 1: Proteinase K Activity in Different Buffer Systems [1]

| Buffer Composition (pH = 8.0, 50°C, 1.25 μg/mL protease K, 15 min incubation) | Relative Proteinase K Activity (%) |

|---|---|

| 30 mM Tris·Cl | 100% |

| 30 mM Tris·Cl; 30 mM EDTA; 5% Tween 20; 0.5% Triton X-100; 800 mM GuHCl | 313% |

| 36 mM Tris·Cl; 36 mM EDTA; 5% Tween 20; 0.36% Triton X-100; 735 mM GuHCl | 301% |

| 10 mM Tris·Cl; 25 mM EDTA; 100 mM NaCl; 0.5% SDS | 128% |

| 10 mM Tris·Cl; 100 mM EDTA; 20 mM NaCl; 1% Sarkosyl | 74% |

| 10 mM Tris·Cl; 50 mM KCl; 1.5 mM MgCl₂; 0.45% Tween 20; 0.5% Triton X-100 | 106% |

| 10 mM Tris·Cl; 100 mM EDTA; 0.5% SDS | 120% |

| 30 mM Tris·Cl; 10 mM EDTA; 1% SDS | 203% |

The significant enhancement of activity in buffers containing both denaturants and detergents (up to 313% of baseline) underscores the importance of buffer optimization for efficient digestion [1].

Mechanism of Nuclease Inactivation

Proteolytic Degradation of Nucleases

Proteinase K inactivates nucleases (DNases and RNases) through the same proteolytic mechanism it employs for other proteins. The enzyme cleaves peptide bonds within the nuclease molecules, disrupting their three-dimensional structure and catalytic activity [9] [10]. This degradation is particularly crucial for protecting nucleic acids during extraction procedures, as most microbial or mammalian DNases and RNases are rapidly inactivated by Proteinase K, especially in the presence of 0.5-1% SDS [1].

Synergistic Effects with Denaturants

Research has demonstrated that Proteinase K alone may be insufficient for complete RNase inactivation in complex biological samples like human serum [12]. High concentrations of Proteinase K must be combined with denaturing concentrations of SDS (anionic surfactant) for irreversible and complete RNase inactivation [12]. The surfactant denatures RNases, making them more susceptible to proteolytic degradation by exposing cleavage sites that would otherwise be buried in the native protein structure [12].

Practical Considerations for Nuclease Inactivation

For effective nuclease inactivation during nucleic acid purification:

- Proteinase K should be used at a ratio of approximately 1:50 (w/w, proteinase K:enzyme) when specifically targeting contaminating nucleases [10].

- Incubation should be performed at 37°C for 30 minutes under standard conditions [10].

- For challenging samples with high RNase content (e.g., blood serum), combine Proteinase K with 0.5-1% SDS and consider adding dithiothreitol (DTT) for complete inactivation [12].

Troubleshooting Common Experimental Issues

Frequently Asked Questions

Table 2: Troubleshooting Guide for Proteinase K Applications

| Question | Answer | Supporting Experimental Evidence |

|---|---|---|

| Why is digestion performed at 50-60°C? | Elevated temperatures unfold protein substrates, making them more accessible. Proteinase K remains stable and exhibits increased activity at these temperatures. [9] [10] | Activity increases severalfold when temperature is raised from 37°C to 50-60°C. [1] |

| How do I completely inactivate Proteinase K? | Heat at >65°C for 10-15 minutes or use serine protease inhibitors (PMSF, AEBSF). [1] [10] | Incubation at 85°C for 10 min effectively terminates enzymatic activity. [13] |

| Can I use Proteinase K directly in PCR? | No, it is used in DNA extraction prior to PCR. Residual activity would degrade the polymerase. [9] | Proteinase K must be inactivated by heat before PCR. [14] |

| Why is my DNA yield low from FFPE samples? | Standard digestion protocols may be insufficient. Try increasing Proteinase K volume or extending digestion time. [15] | Doubling Proteinase K quantity increased DNA yield by 96% from FFPE tissues. [15] |

| How do I verify Proteinase K is active? | Use fluorometric assays with synthetic substrates or casein digestion plate assays measuring clearance zones. [10] | Benzoyl arginine-p-nitroanilide cleavage yields yellow p-nitroaniline measurable at 410nm. [10] |

Advanced Optimization Strategies

For challenging samples such as formalin-fixed, paraffin-embedded (FFPE) tissues, standard Proteinase K protocols may require optimization:

Increased Enzyme Volume: Doubling the quantity of Proteinase K in FFPE tissue digestion resulted in a median increase in DNA yield of 96% compared to the manufacturer's standard protocol [15].

Extended Digestion Time: For FFPE tissues, extending the digestion time from 24 hours to 72 hours can improve DNA yield and integrity, particularly for samples with high cross-linking due to formalin fixation [15].

Modified Deparaffinization Methods: Applying optimized Proteinase K protocols to tissue sections deparaffinized on microscope slides (rather than in centrifuge tubes) generated a further 41% increase in yield for samples with high cellularity (>50,000 epithelial tumor cells/section) [15].

The following workflow diagram illustrates an optimized Proteinase K digestion protocol for difficult samples:

Essential Research Reagent Solutions

Table 3: Key Reagents for Proteinase K-Based Experiments

| Reagent | Function/Application | Example Usage |

|---|---|---|

| Proteinase K | Broad-spectrum serine protease for protein digestion and nuclease inactivation. [9] [1] | Digest contaminating proteins during nucleic acid extraction at 0.2-1 mg/mL. [9] |

| SDS (Sodium Dodecyl Sulfate) | Anionic denaturant that enhances Proteinase K activity by unfolding protein substrates. [1] [12] | Use at 0.5-1% concentration to significantly increase digestion efficiency. [1] |

| EDTA (Ethylenediaminetetraacetic acid) | Chelating agent that binds calcium ions, destabilizing Proteinase K but preserving activity while inhibiting metallonucleases. [1] | Include in digestion buffers at 10-100 mM to inhibit nucleases without completely inactivating Proteinase K. [1] |

| Tris Buffer | Maintaining optimal pH range (7.5-8.5) for Proteinase K activity. [1] | Use at 10-50 mM concentration as the basis for digestion buffers. [1] |

| Guanidinium Salts | Chaotropic agents that denature proteins and enhance Proteinase K activity. [1] [12] | Include at 0.8M concentration to boost activity over 300% compared to standard buffers. [1] |

| PMSF (Phenylmethylsulfonyl fluoride) | Serine protease inhibitor for specific termination of Proteinase K activity. [1] | Add after digestion completion to prevent unwanted proteolysis in downstream applications. [1] |

Proteinase K serves as an indispensable tool in molecular biology due to its unique combination of broad substrate specificity, remarkable stability under denaturing conditions, and efficient nuclease inactivation capabilities. Understanding the precise mechanism of peptide bond cleavage and factors influencing its activity enables researchers to optimize protocols for specific applications, particularly when working with challenging sample types. The troubleshooting guidelines and experimental optimization strategies presented here provide a framework for enhancing experimental outcomes in nucleic acid research and diagnostic applications.

Technical Support Center: Proteinase K Digestion Troubleshooting

Troubleshooting Guide: Common Proteinase K Digestion Issues

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| Incomplete Digestion | Incubation temperature too low | Increase temperature to 50–65°C, the optimal activity range [16]. |

| Incubation time insufficient | Extend digestion time; longer incubations (30 mins to 3 hours) can significantly improve efficiency [17]. | |

| Presence of enzyme inhibitors | Include activators like SDS or urea; SDS can increase activity up to seven-fold [11] [16]. | |

| Sample Degradation | High nuclease content in tissues | For nuclease-rich tissues (e.g., pancreas, liver), keep samples frozen and on ice; ensure rapid lysis [17]. |

| Improper sample storage | Flash-freeze samples in liquid nitrogen and store at -80°C to prevent degradation [17]. | |

| Weak or No Signal in ISH | Under-digestion with Proteinase K | Optimize concentration via titration (1–5 µg/mL for 10 minutes is a good starting point) [18]. |

| Over-digestion with Proteinase K | Reduces signal by destroying tissue morphology; titrate to find concentration that gives strongest signal with preserved structure [18]. | |

| Low DNA Yield/Purity | Enzyme activity compromised by EDTA | While EDTA does not directly inactivate Proteinase K, it chelates calcium, reducing enzyme stability [16]. |

| Inefficient lysis of tissue | Cut tissue into the smallest possible pieces for more efficient digestion and lysis [17]. |

Frequently Asked Questions (FAQs)

Q1: What are the optimal conditions for Proteinase K activity? Proteinase K has a broad effective pH range of 4.0 to 12.5, with an optimal range between pH 7.5 and 8.0 [3] [16]. The optimum reaction temperature is generally 65°C, but a range of 50°C to 65°C is effective for activity, with higher temperatures aiding protein unfolding [3] [16].

Q2: How do I inactivate Proteinase K? Heating to 95°C for 10 minutes is a common method to inactivate Proteinase K, though it may not be 100% effective [16]. For complete inactivation, protease inhibitors such as PMSF or AEBSF (Pefabloc) can be used [16].

Q3: How do ionic strength and metals affect Proteinase K and its substrates? The ionic environment can significantly influence the digestion of specific substrates. For example, in prion research, low ionic strength buffers make PrPSc molecules over 20-fold more sensitive to Proteinase K digestion. The addition of micromolar concentrations of copper or zinc ions under low ionic strength restores the protease resistance of these molecules [19] [20]. This effect is reversible and controls the protein's conformational state and function [19].

Q4: Why is calcium often mentioned with Proteinase K? Proteinase K binds two calcium ions (Ca²⁺), which help maintain the enzyme's structural stability, particularly at higher temperatures, and protect it from autolysis (self-digestion) [16]. Calcium is not required for its proteolytic activity but is crucial for its longevity under demanding conditions [16].

Q5: What are common activators of Proteinase K? Denaturing agents like SDS (sodium dodecyl sulfate) and urea are potent activators of Proteinase K [11] [16]. They unfold protein substrates, making them more accessible to the enzyme and thereby significantly boosting its digestive efficiency [11].

Experimental Protocols for Key Investigations

Protocol 1: Titrating Proteinase K for In Situ Hybridization (ISH)

This protocol is critical for achieving a strong hybridization signal while preserving tissue morphology [18].

- Prepare Sample Sections: Obtain fixed tissue sections on slides.

- Apply Titrated Enzyme: Apply a range of Proteinase K concentrations (e.g., 0, 1, 2, 5, and 10 µg/mL) in your standard buffer to different sections.

- Incubate: Incubate at room temperature for 10 minutes.

- Stop Reaction: Thoroughly rinse slides to stop the digestion.

- Hybridize: Proceed with your standard ISH protocol using the target probe.

- Analyze: Examine slides for hybridization signal intensity and tissue integrity. The optimal concentration produces the highest signal with the least morphological disruption [18].

Protocol 2: Investigating Ionic Strength and Metal Effects on Protease Resistance

This protocol, based on prion research, demonstrates how the ionic environment controls substrate digestion [19] [20].

- Prepare Sample: Use a substrate known for partial protease resistance (e.g., PrPSc from infected brain homogenate).

- Set Buffer Conditions: Create two sets of buffers:

- Set A (Variable Ionic Strength): Low ionic strength buffer vs. high ionic strength buffer.

- Set B (With Metals): Low ionic strength buffer supplemented with zinc or copper ions (micromolar concentrations).

- Digestion: Add a fixed amount of sample to each buffer condition and digest with a standardized amount of Proteinase K.

- Inactivate and Analyze: Heat-inactivate Proteinase K and analyze the digest by Western blotting.

- Expected Outcome: Sensitivity to Proteinase K will be highest in low ionic strength buffer and will be reversed by the addition of transition metals [19] [20].

Parameter Interaction and Experimental Workflow

Key Parameter Relationships for Digestion Efficiency

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function in Experiment |

|---|---|

| Proteinase K | A broad-spectrum serine protease used to digest proteins and inactivate nucleases during nucleic acid purification [11] [16]. |

| SDS (Sodium Dodecyl Sulfate) | A denaturing detergent and potent activator of Proteinase K; unfolds proteins, making them more accessible and increasing enzymatic activity up to seven-fold [11] [16]. |

| Calcium Chloride (CaCl₂) | Used in storage buffers to provide Ca²⁺ ions, which stabilize Proteinase K's structure, protect it from autolysis, and enhance its thermostability [16]. |

| EDTA (Ethylenediaminetetraacetic acid) | A chelating agent that binds metal ions. It is used to deplete Ca²⁺ or other metals, which can help study their role or inhibit metallonucleases, though it may reduce Proteinase K stability [16]. |

| Transition Metal Ions (e.g., Cu²⁺, Zn²⁺) | These ions can directly alter the conformation and protease resistance of specific substrates (e.g., prion proteins), thereby controlling their digestibility independent of the enzyme's own activity [19] [20]. |

The Critical Role of Calcium Ions in Stabilizing Proteinase K and Preventing Autolysis

Proteinase K is a robust serine protease widely used in molecular biology for its ability to digest a broad spectrum of proteins and inactivate nucleases. Its stability under demanding conditions—including the presence of SDS, urea, and elevated temperatures—is crucial for its effectiveness in protocols ranging from nucleic acid purification to tissue digestion. Central to this stability is its interaction with calcium ions (Ca²⁺). Extensive research has demonstrated that calcium plays a multifaceted role: it maintains the enzyme's structural integrity, enhances its resistance to thermal denaturation, and critically, protects it from self-digestion (autolysis). This article examines the mechanistic basis of calcium-dependent stabilization and provides practical guidance for researchers to optimize Proteinase K activity in experimental workflows.

FAQs: Troubleshooting Calcium-Related Issues

Q1: How does calcium specifically protect Proteinase K from autolysis? Calcium ions play a direct structural role in stabilizing the three-dimensional conformation of Proteinase K. The enzyme possesses two calcium-binding sites [21] [22]. The tightly bound calcium (Ca1) is integral to the overall protein scaffold. Removal of this ion triggers long-range structural changes that propagate through the molecule, affecting loops and helices up to 25 Å away from the binding site itself [22]. This altered conformation is not only less active but also more flexible, making susceptible peptide bonds more accessible for autolytic cleavage. By holding the enzyme in a rigid, stable state, calcium binding directly reduces the rate at which Proteinase K molecules digest each other.

Q2: My Proteinase K seems to lose activity quickly. Could calcium concentration be the issue? Yes, insufficient calcium is a common cause of premature activity loss. While Proteinase K retains some proteolytic activity even in the absence of calcium, its stability is severely compromised [23]. For long-term storage, always prepare stock solutions in a buffer containing 1 mM CaCl₂ [2]. Avoid using pure water or buffers containing calcium chelators like EDTA for stock preparation. If your experimental protocol requires EDTA (e.g., to inhibit metal-dependent nucleases), you can add a correspondingly higher concentration of CaCl₂ to ensure free calcium remains available to the enzyme [24].

Q3: Does calcium affect the enzymatic activity of Proteinase K, or just its stability? Calcium is primarily a stability factor, not part of the catalytic mechanism. The catalytic triad (Asp39-His69-Ser224) functions independently of calcium [22] [23]. However, stability and measurable activity are linked. When calcium is removed, the enzyme's thermal stability drops significantly, causing it to denature and lose function more quickly at elevated temperatures. Furthermore, the structural changes induced by calcium loss can reduce substrate affinity, leading to a drop in observed activity over time, even if the initial catalytic rate is largely unchanged [22] [23].

Q4: I need to inactivate Proteinase K after a digestion step. Will EDTA work? EDTA is not a reliable method for immediate inactivation. While EDTA chelates calcium and thereby destabilizes Proteinase K, leading to a gradual loss of activity, it does not instantly stop proteolysis [24]. The most effective and reliable inactivation method is heating to 95°C for 10 minutes [24]. For complete and permanent inactivation, especially in sensitive applications, protease inhibitors such as PMSF or AEBSF (Pefabloc) are recommended [24].

Q5: How do detergents like SDS interact with calcium's stabilizing role? Detergents like SDS are activators of Proteinase K and are often used in digestion buffers to denature substrate proteins, making them more accessible [24] [25]. Fortunately, the stabilizing effect of calcium is so potent that Proteinase K remains active and stable even in buffers containing up to 0.5% SDS [2]. The combination of 1 mM CaCl₂ and SDS in the digestion buffer creates an ideal environment: the calcium protects the enzyme, while the SDS denatures the target proteins, leading to highly efficient digestion.

Troubleshooting Guide: Common Problems and Solutions

| Problem | Potential Cause | Recommended Solution |

|---|---|---|

| Incomplete Digestion | Low calcium concentration leading to enzyme instability. | Add CaCl₂ to the digestion buffer to a final concentration of 1-5 mM [25] [2]. |

| Rapid Loss of Enzyme Activity in Stock Solution | Stock solution prepared in water or Tris without calcium. | Aliquot and store stock solution (20 mg/mL) in 50 mM Tris-HCl, 1 mM CaCl₂, pH 8.0 [2]. |

| Poor Digestion Efficiency in Tissue Samples | Suboptimal buffer conditions for challenging substrates. | Use a digestion buffer containing 0.5-1% SDS and 1 mM CaCl₂ to enhance tissue disruption and enzyme stability [25]. |

| Failed Inactivation | Reliance on EDTA for rapid inactivation. | Inactivate by heating at 95°C for 10 minutes post-digestion [24]. |

| Variable Activity Between Batches | Uncontrolled calcium levels in buffers or environmental factors. | Standardize all digestion buffers to include 1 mM CaCl₂ and avoid pH < 7.5 [24] [2]. |

Experimental Protocols and Data

Protocol: Testing Calcium Dependence of Proteinase K Stability

Objective: To empirically determine the effect of calcium ions on the thermal stability of Proteinase K.

Reagents:

- Proteinase K stock solution (20 mg/mL in 10 mM Tris-HCl, pH 8.0).

- Buffer A: 50 mM Tris-HCl, pH 8.0.

- Buffer B: 50 mM Tris-HCl, 1 mM CaCl₂, pH 8.0.

- Buffer C: 50 mM Tris-HCl, 5 mM EDTA, pH 8.0.

- Substrate: 1 mM Suc-AAPF-pNA in DMF.

Method:

- Set up three reaction mixtures:

- Tube 1 (Control): 100 µL Buffer A + 5 µL Proteinase K stock.

- Tube 2 (+Ca²⁺): 100 µL Buffer B + 5 µL Proteinase K stock.

- Tube 3 (+EDTA): 100 µL Buffer C + 5 µL Proteinase K stock.

- Incubate all tubes at 50°C for 30 minutes.

- Place tubes on ice. Add 10 µL of each mixture to a cuvette containing 990 µL of the respective buffer (A, B, or C).

- Start the reaction by adding 50 µL of the Suc-AAPF-pNA substrate.

- Immediately measure the increase in absorbance at 410 nm over 2 minutes.

- Calculate the relative activity by comparing the rate of absorbance change (ΔA/min) for each condition against the control.

Quantitative Data on Calcium's Impact

Table 1: Effect of Calcium and Temperature on Proteinase K Half-Life

| Condition | Temperature | Estimated Half-Life | Relative Activity (%) |

|---|---|---|---|

| 1 mM CaCl₂ | 50°C | >24 hours [25] | 100 [2] |

| 1 mM CaCl₂ | 65°C | ~30-60 minutes [24] | ~100 (at optimal range) [24] |

| 1 mM EDTA | 50°C | Significantly reduced [22] | ~20 (after depletion) [22] |

| No Additives | 37°C | Reduced due to autolysis [2] | Variable, lower stability [23] |

Table 2: Optimized Buffer Conditions for Specific Applications

| Application | Recommended Buffer Composition | Incubation Conditions |

|---|---|---|

| Standard DNA/RNA Purification | 10-50 mM Tris-HCl, 1 mM CaCl₂, 0.5% SDS, pH 8.0 [24] [2] | 50-65°C for 30 min to 2 hours [24] |

| Tissue Digestion (Lung Burden) | 50 mM Tris-HCl, 1-5 mM CaCl₂, 0.5-1% SDS, pH 8.0 [25] | 56°C for 24-48 hours [25] |

| Prion Protein Digestion | 10-50 mM Tris-HCl, 1 mM CaCl₂, 0.5-1% SDS, pH 8.0 | 37-55°C for 30-60 min [24] |

| In-solution Protein Digestion | 50 mM NH₄HCO₃, 1 mM CaCl₂, pH ~8.0 | 37°C for 4-16 hours |

The Scientist's Toolkit: Essential Reagents

Table 3: Key Research Reagent Solutions

| Reagent | Function in Proteinase K Protocols |

|---|---|

| Calcium Chloride (CaCl₂) | The essential cofactor for stabilizing the enzyme's structure and preventing autolysis. A 1 M stock solution is used to achieve a final working concentration of 1-5 mM [25] [2]. |

| Tris-HCl Buffer (pH 8.0) | Provides the optimal alkaline pH (7.5-12.0) for Proteinase K activity [24] [2]. |

| Sodium Dodecyl Sulfate (SDS) | An activator that denatures substrate proteins, making them more accessible to proteolytic cleavage. Used at concentrations of 0.5-1% [24] [25]. |

| EDTA (Ethylenediaminetetraacetic acid) | A chelating agent used to bind calcium and other metal ions. It is used in nucleic acid purification buffers to inhibit metal-dependent nucleases but requires compensatory calcium for Proteinase K stability [24]. |

| PMSF/AEBSF | Serine protease inhibitors used for the permanent and complete inactivation of Proteinase K after digestion is complete [24]. |

Mechanism Visualization: Calcium Stabilization of Proteinase K

Calcium Binding Prevents Proteinase K Autolysis

Within the context of optimizing Proteinase K digestion times for efficient sample processing, understanding the chemical modulators of enzyme activity is not just beneficial—it is essential. Proteinase K is a robust serine protease widely used in molecular biology to digest proteins and nucleases during nucleic acid purification. However, its activity is significantly influenced by the chemical environment. The presence of certain reagents can either enhance its efficiency or lead to complete inhibition, directly impacting the success of downstream applications such as PCR and sequencing. This guide provides a detailed overview of how common laboratory reagents like SDS, Urea, EDTA, and PMSF modulate Proteinase K activity, offering troubleshooting and protocols to help researchers, scientists, and drug development professionals refine their experimental conditions.

Frequently Asked Questions (FAQs)

1. What is the optimal pH for Proteinase K activity? The optimal pH for Proteinase K activity is in the neutral to slightly basic range, between pH 8.0 and 9.0. The enzyme remains active across a broad pH range (pH 4.0–12.0), but its efficiency is highest within this optimal window [26].

2. At what temperature should I perform Proteinase K digestion? While Proteinase K is active at room temperature, its optimal digestion temperature is 37°C [26]. For some applications, such as DNA extraction from formalin-fixed paraffin-embedded (FFPE) tissues or bacterial samples, a higher incubation temperature of 55–65°C is often used to ensure complete lysis and digestion [26] [27].

3. How long should the Proteinase K incubation be? The incubation time varies significantly with the sample type. It can range from 1–3 hours for bacteria and mammalian cells to several hours or overnight for tough samples like FFPE tissues [26] [27]. Over-incubation can lead to over-digestion and degradation of target molecules [26].

4. Can I dissolve Proteinase K in any solvent? Proteinase K can be dissolved in water or buffers such as Tris-HCl or TE buffer [26]. However, it should not be dissolved in solutions containing high concentrations of strong detergents like SDS, as this can denature and inactivate the enzyme [26].

Troubleshooting Common Issues

| Problem | Possible Cause | Recommended Solution |

|---|---|---|

| Incomplete Digestion | Insufficient incubation time or low enzyme activity. | Increase incubation time; optimize temperature (e.g., 55°C for tissues); confirm reagent is not expired [26] [27]. |

| Degraded DNA/RNA | Over-digestion due to too much enzyme or excessively long incubation. | Titrate Proteinase K to determine the optimal amount; avoid unnecessarily long incubations [26]. |

| Low Enzyme Activity | Incorrect pH or presence of inhibitors. | Ensure reaction pH is between 8.0-9.0; check buffer for contaminants like SDS or EDTA [26]. |

| Enzyme Inactivation | Denaturation during stock solution preparation. | Avoid high concentrations of denaturants like SDS or Urea in the stock solution; store aliquots at -20°C or below [26]. |

The following table summarizes the effects of key chemical modulators on Proteinase K, providing a quick reference for experimental design.

| Reagent | Effect on Proteinase K | Mechanism of Action | Practical Consideration |

|---|---|---|---|

| SDS (Sodium Dodecyl Sulfate) | Inhibitor (at high concentrations) [26] | Strong ionic detergent that denatures and inactivates the enzyme [26]. | Avoid in Proteinase K stock solutions. Can be used in some lysis buffers if diluted. |

| Urea | Inhibitor (at high concentrations) [26] | Chaotropic agent that denatures proteins, disrupting their native structure [26]. | Use at lower concentrations or avoid entirely in the digestion mix. |

| EDTA (Ethylenediaminetetraacetic acid) | Inhibitor [26] [28] | Chelating agent that binds metal ions (e.g., Ca²⁺) essential for Proteinase K's structural stability and activity [26]. | Common in lysis buffers to inhibit metalloproteases. Can be used to stop Proteinase K reaction. |

| PMSF (Phenylmethylsulfonyl fluoride) | Inhibitor [26] [28] | Irreversibly binds to the active site serine residue, inactivating this serine protease [26]. | A common serine protease inhibitor used to quench digestion; add post-incubation. |

| Ca²⁺ (Calcium Ions) | Activator / Stabilizer | Helps maintain the enzyme's active structural conformation. | - |

Experimental Protocol: Testing Digestion Efficiency

This protocol provides a framework for empirically determining the optimal digestion conditions for your specific sample type, which is crucial for research on optimizing Proteinase K digestion time.

1. Sample Preparation:

- Obtain your sample (e.g., tissue, bacterial pellet, mammalian cells).

- For tissues, homogenize the sample in an appropriate lysis buffer. Note that the composition of the lysis buffer is critical, as detergents like SDS can inhibit Proteinase K if present in high concentrations [26] [29].

2. Setting Up Reactions:

- Prepare a series of microcentrifuge tubes with equal amounts of the sample.

- To each tube, add Proteinase K to a final concentration within the typical working range (e.g., 10-20 µl of a 20 mg/mL stock per mL of reaction) [27].

- Variable to test: Incubation time. Set up parallel reactions and incubate them at the optimal temperature (e.g., 55°C) for different durations (e.g., 30 min, 1 hr, 2 hr, 3 hr, overnight) [26] [27].

3. Inactivation:

- After the respective incubation times, inactivate Proteinase K by heating the samples to 95°C for 10 minutes or by adding inhibitors like PMSF or EDTA [26] [27] [28].

4. Analysis:

- Visual Inspection: A clear lysate after centrifugation often indicates complete digestion [27].

- Downstream Application: The best metric for success is the yield and quality of the extracted nucleic acid in your intended application, such as PCR amplification or sequencing.

Research Reagent Solutions

The following table lists key reagents used in experiments involving Proteinase K and their primary functions.

| Reagent | Function in Context |

|---|---|

| Proteinase K | A broad-spectrum serine protease used to digest proteins and nucleases in samples. |

| Tris-HCl Buffer | A common buffer used to maintain the optimal pH (8.0-9.0) for Proteinase K activity. |

| EDTA | A chelating agent used to inhibit metalloproteases and, subsequently, to inactivate Proteinase K. |

| PMSF | A serine protease inhibitor used to quench Proteinase K activity after digestion. |

| SDS | A strong ionic detergent used for cell lysis; it inhibits Proteinase K at high concentrations. |

| CaCl₂ | A source of calcium ions that helps stabilize and maintain Proteinase K activity. |

Visualizing the Mechanisms of Modulation

The diagram below illustrates how different chemicals influence Proteinase K activity, either by direct inhibition, denaturation, or stabilization.

Experimental Workflow for Digestion Optimization

This flowchart outlines the key decision points and steps in a typical Proteinase K digestion experiment, from sample preparation to analysis.

Proteinase K in Practice: Protocols for Diverse Sample Types and Applications

In molecular biology research, particularly in studies focused on optimizing proteinase K digestion, the reliability of every experimental result is contingent upon the quality of the foundational reagents used. The preparation and management of standard stock solutions are critical procedural pillars that directly impact the efficacy and reproducibility of downstream applications. This guide provides detailed protocols and troubleshooting advice to ensure the highest standards in the preparation of stock solutions, with a specific emphasis on supporting robust proteinase K digestion experiments.

Key Reagents and Solutions for Proteinase K Research

The following table details essential reagents commonly used in workflows involving proteinase K.

Table 1: Research Reagent Solutions for Proteinase K Protocols

| Reagent/Solution | Function/Role in Experimentation |

|---|---|

| Proteinase K | A broad-spectrum serine protease used to digest proteins and nucleases in DNA/RNA extraction, preventing degradation of the target nucleic acids [30] [31]. |

| Tris Buffers (e.g., TAEs, TBE) | Maintain a stable pH environment during enzymatic reactions or electrophoresis, crucial for consistent proteinase K activity and nucleic acid separation [32] [33]. |

| EDTA (Ethylenediaminetetraacetic acid) | A chelating agent that inhibits metal-dependent nucleases by binding magnesium ions; often included in lysis buffers for nucleic acid extraction [30] [31]. |

| DTT (Dithiothreitol) | A reducing agent that breaks disulfide bonds in mucins, effective for homogenizing viscous samples like sputum to improve nucleic acid extraction efficiency [34]. |

Fundamental Calculations for Solution Preparation

Accurate preparation of stock and working solutions requires a firm grasp of basic chemical calculations. The following equations are indispensable.

1. The Dilution Equation

This formula is used to calculate the volume of a concentrated stock solution needed to prepare a desired volume of a less concentrated solution.

(C1)(V1) = (C2)(V2) [35] [32]

Where:

- C1 = Concentration of the initial (stock) solution

- V1 = Volume of the initial (stock) solution to use

- C2 = Concentration of the final (working) solution

- V2 = Volume of the final (working) solution

Example: To prepare 250 mL of a 0.3 µg/mL Ca²⁺ solution from a 1000 µg/mL stock:

(1000 µg/mL)(V1) = (0.3 µg/mL)(250 mL)

V1 = [(0.3)(250)] / 1000 = 0.075 mL = 75 µL [35]

2. Molarity Calculations

Molarity (M) is the number of moles of a solute per liter of solution.

Molarity (M) = moles of solute / liters of solution [32]

For example, 1M sodium chloride (NaCl) contains 58.44 g of NaCl (its molecular weight) dissolved in 1 liter of solution [32].

3. Acid Molarity from Weight Percentage

The molarity of a concentrated acid can be calculated using its density and weight percentage.

[(% acid x density) / Molecular Weight] x 10 = Molarity [35]

Example: For 70.4% nitric acid (density 1.42 g/mL, MW 63.01 g/mole):

[(70.4 x 1.42) / 63.01] x 10 = 15.9 M [35]

Standard Solution Preparation & Handling Protocols

General Workflow for Stock Solution Preparation

The diagram below outlines the logical sequence for preparing high-quality stock solutions.

Detailed Procedural Guidelines

Calculations and Measurements

- Weighing Solids: Use an appropriate analytical balance. For hygroscopic or volatile materials, use a tightly sealed container and work efficiently [32].

- Measuring Liquids: For large volumes (>5 mL), use a graduated cylinder placed on a flat surface and read the volume at the middle of the meniscus at eye level. For smaller volumes, use a calibrated pipette [32]. Crucially, never insert pipettes directly into the stock solution container; always pour an aliquot into a separate vessel to avoid contaminating the stock [35].

Mixing and pH Adjustment

- Add solutes to a volume of solvent slightly less than the final required volume.

- Adjust the pH at the temperature the solution will be used, as pH is temperature-dependent. Use a properly calibrated pH meter [36]. Avoid "overshooting" the target pH, as repeatedly adding acid or base alters the final ionic strength of the buffer [36].

Final Volume Makeup

- After the solute is fully dissolved and the pH is adjusted, add the solvent to reach the final exact volume. This practice of "making up to volume" ensures the correct molarity, as adding solid chemicals can increase the total volume [32].

Preparation of a Proteinase K Stock Solution

- Procedure: Weigh the desired amount of Proteinase K powder. Add it to a suitable tube with an appropriate volume of buffer (e.g., Tris-HCl, TE buffer) or nuclease-free water. Vortex or pipette to mix thoroughly. A typical stock concentration is 20 mg/mL [30] [31].

- Storage: Aliquot and store at -20 °C or below to maintain long-term stability and activity. Avoid repeated freeze-thaw cycles [31].

Optimal Storage Conditions for Stock Solutions

Adhering to proper storage protocols is essential for maintaining solution integrity.

Table 2: Storage and Handling Guidelines for Common Solutions

| Solution Type | Recommended Storage | Shelf-Life Consideration | Key Handling Precautions |

|---|---|---|---|

| Inorganic Standard Solutions | As specified by protocol; often at room temperature or 4°C. | Replace at least annually due to risks of transpiration and concentration changes, even if chemically stable [35]. | - Uncap for minimal time.- Never return aliquots to the stock container.- Avoid pipetting directly from the stock bottle [35]. |

| Proteinase K Solution | -20°C or below [31]. | Stable for years if stored properly and protected from contamination. | Aliquot to avoid repeated freeze-thaw cycles. Protect from heat and moisture [31]. |

| TAE/TBE Running Buffers | Room temperature (for 1x working solution) [33]. | Discard if solution becomes cloudy or discolored [33]. | For stock solutions, warm to 37°C if precipitation is observed, and mix until dissolved before dilution [33]. |

Troubleshooting Guide & FAQs

Frequently Asked Questions

Q1: Why is it better to prepare a working buffer at its required concentration and pH rather than diluting a pH-adjusted concentrated stock? Diluting a pH-adjusted concentrated stock can lead to a significant shift in the final pH. For example, diluting a 2 M sodium borate stock (pH 9.4) to 500 mM resulted in a pH of 9.33. Similarly, diluting a 1 M phosphate buffer (pH 2.50) to 500 mM resulted in a pH of 2.58. For reproducible results, it is best to prepare the buffer at the final working concentration and pH [36].

Q2: What is the difference between "ppm" (parts per million) and "μg/mL"?

This is a common source of error. 1 ppm is equal to 1 μg/g (weight per weight). To convert between ppm (μg/g) and μg/mL (weight per volume), you must know the density of the solution: (μg/g) * (density in g/mL) = μg/mL [35]. For aqueous solutions with density close to 1, they are often used interchangeably, but this is not accurate for solutions containing acids or other dense components.

Q3: What happens if I use too much Proteinase K in my digestion? Using an excessive amount of Proteinase K can lead to over-digestion. In DNA extraction protocols, this can result in the degradation of the DNA itself and reduced yield. Over-digestion may also release unwanted inhibitors that interfere with downstream applications like PCR [31]. Always titrate the enzyme to find the optimal amount for your specific sample type.

Q4: Can I use a glass pipette with all my standard solutions? No. You must never use glass pipettes or transfer devices with standard solutions containing HF (hydrofluoric acid), as it attacks glass. This precaution also applies to solutions with trace HF or complexed fluorides, which can attack glass just as readily [35].

Common Problems and Solutions

Table 3: Troubleshooting Common Issues in Stock Solution Preparation

| Problem | Potential Cause | Solution |

|---|---|---|

| Poor reproducibility between buffer batches. | Vague preparation description; pH adjustment errors; measuring pH at wrong temperature. | Record procedure in exquisite detail: specify salt forms, acid/base molarity for pH adjustment, and measure pH at usage temperature [36]. |

| Unexpected precipitation in buffer stock. | Storage at low temperatures; exceeding solubility limit. | Warm the solution to 37°C and mix until completely dissolved prior to dilution [33]. |

| Decreased activity of Proteinase K over time. | Repeated freeze-thaw cycles; improper storage temperature; contamination. | Aliquot the stock solution and store at -20°C or below. Avoid multiple freeze-thaw cycles [31]. |

| Inaccurate concentration after preparation. | Assuming weight (g) is equivalent to volume (mL) for non-aqueous solutions. | For precise work, prepare solutions by weight or account for the density of the solution, especially when acids are involved [35]. |

The meticulous preparation and management of standard stock solutions are not merely preliminary tasks but are integral to the success and validity of sophisticated research, such as optimizing proteinase K digestion. By adhering to the detailed protocols, calculations, and storage guidelines outlined in this document, researchers can ensure the highest levels of accuracy, reproducibility, and experimental integrity. A rigorous approach to these fundamental practices is the cornerstone of reliable and impactful scientific discovery.

Optimizing Digestion Time and Temperature for Maximum DNA/RNA Yield

Frequently Asked Questions (FAQs)

Q1: What is the typical working concentration for a proteinase K stock solution? Proteinase K is commonly prepared as a stock solution at concentrations ranging from 10 to 100 mg/mL [37]. For many experimental protocols, a volume of 10-20 µL of a 20 mg/mL stock solution is used [38].

Q2: Can proteinase K be inactivated, and how? Yes, proteinase K can be inactivated. A common method is heat inactivation at 95°C for a period of time [38]. This is a crucial step to prevent unwanted digestion of your target nucleic acids after the initial digestion is complete.

Q3: My tissue lysate appears turbid after proteinase K digestion. What does this mean? A turbid lysate often indicates the presence of indigestible protein fibers, which is common when working with fibrous tissues like muscle, heart, or skin, as well as brain tissue and RNAlater-stabilized tissues [39]. To resolve this, centrifuge the lysate at maximum speed for 3 minutes to pellet these fibers before proceeding to the next step [39].

Q4: What happens if I use too much proteinase K? Using an excessive amount of proteinase K can lead to over-digestion. This may result in the degradation of your target DNA or RNA, reducing yield and potentially releasing inhibitors that can interfere with downstream applications [37]. It is important to titrate the enzyme for your specific application.

Troubleshooting Guide

| Problem | Possible Cause | Solution |

|---|---|---|

| Low DNA/RNA Yield | Incomplete tissue digestion or inefficient lysis [39] [40]. | Implement a pre-digestion proteinase K step [40]. For fibrous tissues, ensure they are cut into the smallest possible pieces or ground with liquid nitrogen [39]. |

| DNA degradation in nuclease-rich tissues [39]. | Keep samples frozen and on ice during preparation. For tissues like pancreas, intestine, kidney, and liver, use the recommended amount of Proteinase K and ensure proper storage at -80°C [39]. | |

| DNA Degradation | Tissue pieces are too large [39]. | Cut tissue into small pieces or use a freeze-grinding method in liquid nitrogen to destroy the tissue matrix before digestion [41] [39]. |

| High nuclease activity in soft organ tissues [39]. | Process samples quickly, keep them frozen, and use ice during preparation. Ensure proteinase K is added promptly to inactivate nucleases [39]. | |

| Protein Contamination | Incomplete digestion of the tissue sample [39]. | Extend the lysis time by 30 minutes to 3 hours after the tissue appears dissolved to ensure complete protein degradation [39]. |

| Membrane clogged with tissue fibers [39]. | Centrifuge the lysate at maximum speed for 3 minutes to remove indigestible fibers before loading the supernatant onto the binding column [39]. |

Optimizing Digestion Conditions: Experimental Data

The tables below summarize key experimental findings from the literature on optimizing proteinase K digestion for nucleic acid yield.

| Proteinase K Protocol | Description | Median DNA Yield | Change from Baseline |

|---|---|---|---|

| Protocol 1 (Baseline) | 20 µL for 24 hours (manufacturer's protocol) | Baseline | - |

| Protocol 2 (Doubled Enzyme) | 20 µL for 5 hours, topped up with a further 20 µL for 19 hours | +96% | 96% increase |

| Protocol 3 (Extended Time) | 20 µL for 72 hours | Data not statistically significant | - |

| Sample Type | Temperature (°C) | Incubation Time | Key Notes |

|---|---|---|---|

| FFPE Tissue | 55 - 56 | Several hours to overnight [38] | An optimized protocol can drastically reduce sample failure rates for sequencing [15]. |

| Bacteria | 55 (or 37 in some protocols) | 1 - 3 hours [38] | Temperature can depend on the specific protocol and bacterial strain. |

| Mammalian Cells | 37 - 65 [37] [38] | 1 hour to overnight [38] | Shorter digestions often use higher temperatures (50-65°C); longer incubations (overnight) use 37°C [38]. |

| General Use | 37 (Optimal) | 30 mins to several hours [37] | Active over a wide range, but 37°C is the optimal temperature for enzyme activity [37]. |

Detailed Experimental Protocols

Protocol 1: Optimizing Proteinase K Digestion for Challenging FFPE Samples

This protocol, adapted from a study that significantly improved DNA yield from FFPE tissues, involves doubling the standard amount of proteinase K [15].

Methodology:

- Deparaffinization: Place 10 sections of 4 µm FFPE tissue scrolls into a 1.5 mL centrifuge tube. Deparaffinize by vortexing in 1 mL xylene substitute for 10 seconds, then centrifuge for 2 minutes to pellet the tissue. Remove the supernatant and repeat the wash with 1 mL of 100% ethanol. After removing the ethanol, air-dry the pellet for 10 minutes [15].

- Proteinase K Digestion: Use a commercial DNA extraction kit (e.g., QIAamp DNA FFPE Tissue Kit) but modify the digestion step as follows:

- Add 20 µL of proteinase K (20 mg/mL) to the tube and incubate at 56°C for 5 hours.

- After 5 hours, add a second 20 µL aliquot of proteinase K.

- Continue the incubation at 56°C for a further 19 hours (24 hours total) [15].

- Post-Digestion and Elution: Follow the remaining steps of the manufacturer's protocol for DNA purification and elution [15].

Protocol 2: Enhancing RNA Yield from Difficult Fresh-Frozen Tissues

This protocol highlights the introduction of a proteinase K digestion step to significantly improve RNA yield from challenging tissues like breast and testis [40].

Methodology:

- Tissue Lysis: Homogenize fresh-frozen tissue samples. The study successfully used both a pestle and TissueLyser, noting that the pestle method was fast and effective [40].

- Proteinase K Digestion: Use the AllPrep DNA/RNA/miRNA Universal kit (Qiagen #80224). A key feature of this protocol is the incorporated proteinase K digestion step which occurs after tissue lysis and before nucleic acid binding to the silica membrane. Follow the kit instructions for this step precisely [40].

- DNase Digestion and Purification: The protocol includes an on-column DNase digestion step for RNA purification. Complete the remaining steps of the kit's protocol for the simultaneous extraction of DNA and total RNA [40].

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Proteinase K Digestion |

|---|---|

| Proteinase K | A broad-spectrum serine protease that digests proteins and inactivates nucleases (DNases and RNases) during cell lysis, protecting the nucleic acids to be extracted [37] [38]. |

| EDTA (Ethylenediaminetetraacetic acid) | A chelating agent included in lysis buffers. It binds metal ions that are essential co-factors for many nucleases, thereby further inhibiting DNA/RNA degradation [37] [38]. |

| SDS (Sodium Dodecyl Sulfate) | An ionic detergent used in lysis buffers to denature proteins and disrupt cellular membranes. Note that high concentrations can denature and inactivate proteinase K [37]. |

| Tris-HCl Buffer | A common buffer used to maintain the optimal pH for proteinase K activity, which is typically in the range of pH 8.0 to 9.0 [37]. |

| Silica Spin Columns / Magnetic Beads | The core of most modern extraction kits. Under high-salt conditions, DNA and RNA bind to the silica surface, allowing contaminants to be washed away before elution in a low-salt buffer [41] [40]. |

Workflow and Pathway Diagrams

Proteinase K Optimization Workflow

Experimental Design for Protocol Optimization

Sample-Specific Protocol Adjustments for Tissues, Blood, and Cultured Cells

FAQs on Proteinase K Digestion

Q1: What is the primary function of Proteinase K in nucleic acid extraction? Proteinase K is a broad-spectrum serine protease used to digest harmful nucleases and cellular proteins during the lysis step of nucleic acid extraction. This process releases DNA or RNA from cells and protects the nucleic acids from degradation by inactivating nucleases [42] [43].

Q2: How do I know if Proteinase K digestion is complete? The most straightforward indicator of complete digestion is a clear cell lysate solution. If the solution remains cloudy after the initial incubation period, you should extend the digestion time. Caution is advised, as excessively long digestion, especially with high volumes of Proteinase K, can lead to DNA degradation [43].

Q3: What are the optimal pH and temperature conditions for Proteinase K activity? Proteinase K is active over a wide pH range but exhibits highest activity at a neutral to slightly basic pH of 8.0–9.0 [42]. While it can work at room temperature, its optimal activity for most applications is 37 °C. Some protocols, particularly for tissue lysis, use higher temperatures (e.g., 55–65°C) to increase efficiency [42] [43].

Q4: What common reagents can inhibit Proteinase K? Proteinase K can be inhibited by several reagents [42]:

- Denaturants: High concentrations of SDS, urea, or chaotropic salts can denature and inactivate the enzyme.

- Chelating Agents: EDTA can inhibit activity by binding to metal ions essential for the enzyme's function.

- Specific Protease Inhibitors: Reagents like phenylmethylsulfonyl fluoride (PMSF) can irreversibly inhibit Proteinase K.

Q5: What happens if I use too much Proteinase K? Using an excessive amount of Proteinase K can lead to over-digestion. This may degrade your target DNA or protein, reducing yield and quality. It can also cause the release of unwanted inhibitors from the sample, such as heme or humic acids, which can interfere with downstream applications like PCR [42].

Troubleshooting Guides

Common Issues and Solutions for Proteinase K Digestion

| Problem | Potential Cause | Recommended Solution |

|---|---|---|

| Incomplete Digestion | Insufficient incubation time or low enzyme activity. | Extend incubation time; ensure fresh, properly stored Proteinase K is used [43]. |

| Low DNA/RNA Yield | Over-digestion degrading nucleic acids; incorrect enzyme concentration. | Titrate Proteinase K amount; avoid excessively long digestion times; inactivate enzyme after digestion (e.g., 95°C incubation) [42] [43]. |

| Inhibition of Downstream Applications | Co-purification of inhibitors (e.g., heme) due to over-digestion; carryover of Proteinase K. | Clean up nucleic acids post-extraction (e.g., ethanol precipitation); ensure proper heat inactivation of Proteinase K [42]. |

| No Activity | Enzyme inactivated by denaturants (e.g., SDS) or improper storage. | Avoid exposing Proteinase K to high concentrations of inhibitors; aliquot and store at -20°C or below [42]. |

Sample-Specific Optimization Table

The following table summarizes key parameters for optimizing Proteinase K digestion across different sample types. These are general guidelines and may require further optimization for your specific experiment.

| Sample Type | Recommended Digestion Temperature | Recommended Digestion Time | Additional Notes & Considerations |

|---|---|---|---|

| Formalin-Fixed, Paraffin-Embedded (FFPE) Tissue | 55–56°C [43] | Several hours to overnight [43] | Requires extended digestion times due to protein cross-linking from formalin fixation. |

| Bacteria | ~55°C [43] | 1–3 hours [43] | Temperature can vary; some protocols use 37°C. |

| Mammalian Cells (Culture) | 37°C (long incubations) or 50–65°C (shorter incubations) [43] | 1 hour to overnight [43] | Higher temperatures correlate with shorter digestion periods. |

| Blood | 37–56°C [42] | 30 minutes to several hours [42] | Often used with EDTA to chelate Mg2+ and inhibit nucleases [43]. |

| Solid Tissues (e.g., Liver, Lung) | 37–65°C [42] | Varies widely; often several hours [42] | Homogenization is typically required prior to digestion to create a uniform suspension. |

Experimental Workflow for Digestion Optimization

The diagram below outlines a logical workflow for developing and troubleshooting a Proteinase K digestion protocol.

Research Reagent Solutions

Essential materials and reagents for experiments involving Proteinase K digestion.

| Reagent | Function in the Protocol |

|---|---|

| Proteinase K | The core enzyme for digesting proteins and nucleases to release and protect nucleic acids [42] [43]. |

| Lysis Buffer | Typically contains detergents (e.g., SDS) to disrupt cell membranes and create an environment for Proteinase K activity. Note: SDS concentration must be compatible [42]. |

| EDTA (Ethylenediaminetetraacetic acid) | A chelating agent that inhibits Mg2+-dependent nucleases, providing an additional layer of protection for DNA [43]. |

| Tris-HCl Buffer | A common buffer used to maintain the optimal pH (8.0-9.0) for Proteinase K activity [42]. |

| Phenol/Chloroform | Used for nucleic acid purification after digestion to separate DNA from proteins and other cellular debris [43]. |

Troubleshooting Guides and FAQs

Proteinase K Digestion

Q: How do I determine the correct Proteinase K digestion time for my sample? A: Digestion time depends heavily on your sample type and fixation method. Incomplete digestion is indicated by a lack of a clear lysed cell solution. If you do not see a clear solution after the initial incubation, you should extend the incubation time. However, for mammalian cells, be cautious as excessively long digestions may lead to DNA degradation [44].

Q: My DNA yield is low after Proteinase K digestion from FFPE tissue. What should I check? A: For Formalin-Fixed Paraffin-Embedded (FFPE) tissues, digestion should be carried out for several hours to overnight at a temperature of 55-56°C to efficiently reverse cross-links and release nucleic acids. Ensure the recommended temperature range is precisely maintained for optimal enzyme activity [44].

Prion Disease Research

Q: What are the challenges in detecting biomarkers for latent neurodegenerative conditions like prion disease? A: Research indicates that detecting early, latent stages of neurodegeneration is complex. Studies in murine models have shown that neuronal stress, such as that induced by the ablation of the mitochondrial fission protein Drp1, can trigger the integrated stress response (ISR), culminating in neuronal expression of cytokines like Fgf21. The induction of Fgf21 has been observed in mechanistically independent mouse models of protein misfolding-associated neurodegeneration, including tauopathy and prion disease, highlighting its potential as an early biomarker [45].

Lung Burden Analysis

Q: What techniques are used to quantify lung burden for materials like Multi-Walled Carbon Nanotubes (MWCNTs)? A: Air sampling is conducted using pumps operating at a defined flow rate (e.g., 2–4 L min⁻¹), with samples collected on quartz-fiber filters. The elemental carbon (EC) content, which serves as a measure of the CNT mass, is then analyzed according to established methods like NIOSH Method 5040, which is based on a thermal-optical technique. To confirm the presence of characteristic MWCNT structures, additional samples can be collected on mixed cellulose ester (MCE) filters for analysis by Transmission Electron Microscopy (TEM) [46].

Experimental Protocols & Data

Proteinase K Digestion Conditions by Sample Type

The following table summarizes key parameters for optimizing Proteinase K digestion across various sample types encountered in advanced research applications [44].

Table 1: Proteinase K Digestion Guide for Different Sample Types

| Sample Type | Typical Digestion Temperature | Typical Digestion Duration | Key Considerations |

|---|---|---|---|

| FFPE Tissues | 55-56°C | Several hours to overnight | Critical for reversing cross-links from formalin fixation. |

| Bacteria | 55°C (37°C also used) | 1 - 3 hours | Temperature may vary based on protocol and bacterial strain. |

| Mammalian Cells | 37°C (for long incubation) / 50-65°C (for shorter incubation) | 1 - 12 hours | Duration and temperature are highly dependent on cell type and experimental objectives. Higher temperatures often allow for shorter incubation. |

| General Inactivation | 95°C | 10-15 minutes | Essential to halt Proteinase K activity after digestion. |

Molecular Profiling for Neurodegenerative Research

Protocol: Investigating Transcriptomic Signatures in Neurological Disorders

- Data Acquisition: Identify and download relevant public domain microarray or RNA-seq datasets from repositories like GEO DataSets (http://www.ncbi.nlm.nih.gov/gds/). For cohesive analysis, ensure datasets use a consistent platform and, where possible, are from similar genetic backgrounds and ages [47].

- Quality Control & Normalization: Perform quality control and normalization of raw data files using appropriate software (e.g., Affymetrix Expression Console with the RMA procedure). Remove probes with low average expression [47].

- Network Analysis: Use network analysis tools like BioLayout Express 3D to calculate a Pearson correlation matrix and construct a network graph. A correlation cutoff (e.g., r = 0.9) is applied to define edges between genes[none].

- Cluster Identification: Employ a clustering algorithm (e.g., Markov clustering algorithm - MCL) to identify groups of co-expressed genes. These clusters represent genes with similar biological roles or regulatory networks [47].

- Functional Validation: Validate the biological significance of the identified clusters using pathway analysis software (e.g., Ingenuity Pathway Analysis) and databases of human disease and knockout mouse phenotypes (e.g., MouseMine) [47]. This helps identify novel candidate genes involved in neurological health and disease.

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions

| Item | Function / Application |

|---|---|

| Proteinase K | A broad-spectrum serine protease used to digest proteins and inactivate nucleases during nucleic acid extraction from tissues, cells, and FFPE samples [44]. |

| EDTA (Ethylenediaminetetraacetic acid) | A chelating agent used in lysis buffers to inhibit Mg2+-dependent nucleases, thereby protecting DNA and RNA from degradation during extraction [44]. |

| Formalin-Fixed Paraffin-Embedded (FFPE) Tissue | The standard in pathology for long-term tissue preservation, though it introduces cross-links that require optimized digestion for nucleic acid extraction [45] [44]. |

| Affymetrix Microarray Platforms | Tools for genome-wide expression profiling, enabling the analysis of transcriptomic changes in various biological conditions, including neurological diseases [47]. |

| Oncomine Tumor Mutational Load Assay | A targeted next-generation sequencing panel used for estimating Tumor Mutational Burden (TMB), a predictive biomarker for immunotherapy [45]. |

Experimental Workflow Diagrams

Proteinase K Digestion Workflow

Integrated Stress Response in Neurodegeneration

MWCNT Lung Burden Analysis

Integrating Proteinase K into Automated Workflows and Point-of-Care Diagnostics

Frequently Asked Questions (FAQs)

Q1: How can Proteinase K be inactivated in an automated workflow to prevent interference with downstream enzymatic steps? Proteinase K can be efficiently inactivated using thermolabile variants. Recombinant thermolabile Proteinase K is completely inactivated by incubation at 55°C for just 10 minutes, enabling subsequent enzymatic steps in the same reaction vessel without purification. This streamlines automated workflows, improves yield, reduces sample loss, and prevents enzyme carryover [48].

Q2: What are the key parameters to optimize for Proteinase K digestion in automated high-throughput systems? For automation, diligent assessment of sample type, protocol design, reagents, and incubation conditions is crucial. An automated liquid handling workstation provides superior control over key parameters [49]. Optimal conditions to program include:

- Denaturation: Use of volatile solvents like 2-2-2 trifluoroethanol (TFE) at 50% (v/v) and temperatures of ~58.6°C for effective denaturation that is MS-compatible and easy to automate [49].

- Digestion Time: Incubation times can vary from 1 hour to overnight, depending on the sample type (e.g., bacteria, mammalian cells, or FFPE tissues) [50].

- Enzyme-to-Substrate Ratio: This is a critical variable that must be optimized for the specific sample input [49].

Q3: What is the significance of Proteinase K in the growing point-of-care (PoC) diagnostics market? Proteinase K plays a vital role in PoC diagnostic test preparation. It breaks down protein components of the cell membrane to allow access to genetic material and removes nucleases that degrade DNA and RNA. This is essential for faster, on-site testing, facilitating quicker diagnosis and treatment decisions, which is a key driver in the expanding PoC market [51].

Troubleshooting Guides

Problem: Low DNA Yield

This is a common issue across various sample types in automated nucleic acid extraction protocols. The causes and solutions are detailed in the table below.

| Problem | Cause | Solution |

|---|---|---|

| General Low Yield | Incomplete tissue lysis due to large tissue pieces. | Cut tissue into the smallest possible pieces or use liquid nitrogen grinding [52]. |

| Column overload from DNA-rich tissues (e.g., liver, spleen). | Reduce the amount of input material [52]. | |

| Blood Samples | Sample age-related DNA degradation. | Use fresh, unfrozen whole blood less than one week old [52]. |

| Formation of hemoglobin precipitates clogging the membrane. | For species with high hemoglobin content, reduce Proteinase K lysis time (e.g., from 5 to 3 minutes) [52]. | |

| FFPE Samples | Incomplete digestion with standard Proteinase K volume. | Doubling the quantity of Proteinase K can increase DNA yield by a median of 96% [15]. |

Problem: DNA Degradation

| Problem | Cause | Solution |

|---|---|---|

| Sample Storage | Improper sample storage before processing. | Flash-freeze tissue samples with liquid nitrogen and store at -80°C. Use stabilizing reagents like RNAlater for storage at 4°C or -20°C [52]. |

| High Nuclease Tissues | DNase activity in tissues like pancreas, liver, kidney. | Keep samples frozen and on ice during preparation. Use recommended input material and ensure sufficient Proteinase K is used [52]. |

Problem: Protein or Salt Contamination

| Problem | Cause | Solution |

|---|---|---|

| Protein Contamination | Incomplete digestion or clogged membrane with tissue fibers. | Centrifuge lysate at max speed for 3 minutes to pellet fibers. For fibrous tissues, do not exceed 12-15 mg input material [52]. |

| Salt Contamination | Carryover of guanidine salt from binding buffer. | Avoid pipetting lysate onto the upper column area, avoid transferring foam, and gently close caps to prevent splashing [52]. |

Experimental Protocols & Data

Protocol 1: Optimizing Proteinase K Digestion for FFPE Tissues

This protocol is adapted from a study that systematically evaluated digest conditions to improve DNA yield and integrity for sequencing [15].

Methodology:

- Deparaffinization: Perform in centrifuge tubes using 1 ml xylene substitute, followed by 100% ethanol washes.

- Proteinase K Digest: Use the QIAamp DNA FFPE Tissue Kit and test the following digest protocols on 10 sections of 4 µm each:

- Protocol 1 (Standard): 20 µl Proteinase K for 24 hours.

- Protocol 2 (Increased Enzyme): 20 µl Proteinase K for 5 hours, topped up with a further 20 µl for another 19 hours (24 hours total).

- Protocol 3 (Extended Time): 20 µl Proteinase K for 72 hours.

- DNA Elution: Elute DNA in 50 µl Tris-EDTA buffer.

- Quantification: Assay DNA concentration by PicoGreen spectrofluorometry.

Results Summary:

| Digest Protocol | Median Change in DNA Yield | Key Finding |

|---|---|---|

| Standard (20 µl, 24 hr) | Baseline | Control group for comparison [15]. |

| Increased Enzyme (40 µl total, 24 hr) | +96% | Doubling the enzyme quantity significantly boosts yield [15]. |

| Extended Time (20 µl, 72 hr) | Not specified (less effective than increased enzyme) | Increasing enzyme volume was more effective than extending time alone [15]. |

Protocol 2: Automating Sample Preparation for Proteomics